Helpful Tips

For over 50 years Clenaware has been designing and manufacturing warewashing equipment and we understand that your equipment is an investment in your business.

The tips below give helpful advice on how to get the most out of your product, from prolonging the life of your machine, to achieving excellent results each and every time you wash your glass or tableware.

Glass and Dishwashers

Clenaware warewashers are designed to be a fully integrated machines with everything you need built into them. Our machines include a rinse booster pump, a waste pump and chemical injection and sensoring. They also includ a built-in self diagnostics system and are WRAS approved.

Did you know? Clenaware Systems has been designing and manufacturing ware washing equipment for over 50 years and we are a UK company that only designs and builds its products in the UK.

Tips To Help Prevent Breakdowns And Unnecessary Call Outs

- Follow the daily cleaning maintenance schedule as listed on the Care Card. Unnecessary dirt build up can cause issues with the working of the machine, such as dirt build up around the Door Frame. This can stop the machine Door Switch activating leading you to believe the machine isn’t working.

- At the end of the working session allow the machine to fully closedown when you select the closedown cycle. Once the cycle is fully finished isolate the power to the machine. If you prematurely switch off the machine, the next time you go to use it the machine won’t start up correctly.

- In the colder winter months, the water coming into the machine will take longer to heat. So, at the start of the working session have a little patience and DO NOT press any buttons whilst waiting for the machine to heat. If you do press buttons unnecessarily this will ‘confuse’ the machine and it won’t fully operate, leading you to believe the machine has broken down.

- If you have any glass breakages in the machine, ensure that all of the glass is removed and make sure all of the Wash Tank Filters are firmly in place as these prevent broken glass from getting into the Pumps.

- Use good quality chemicals in the machine, this not only gives you better wash results but also helps to keep the machine clean. It also stops the detergent and rinseaid indicator lights on the Control Panel from going orange, which can lead you to believe the chemicals aren’t dosing properly.

- If you’re in a hard water area fitting a water treatment to the machine will prevent breakdowns that can result from limescale build up inside the machine. Parts such as heating elements and hoses can get ‘caked’ with limescale and become less efficient.

- If you have done all of the above then the Technical Support Team will be available to diagnose over the phone and if required they will book an engineer visit to site.

Tips To Keep Your Machine Running Efficiently Between Services

- Follow the maintenance schedule every day, remove Wash Arms, Rinse Arms and the Filters and clean them.

- If you want to keep the interior of the machine clean, use Renovate powder once a week to clean the Wash Tank. Use one scoop of powder and then select a wash cycle without any glasses in the glass basket.

- Invest in a Clenaware Machine Cleaning Kit which contains brushes designed specifically for cleaning inside the Wash and Rinse Arms and machine. The Cabinet Brush in the kit is ideal for sweeping out any dirt from inside the tank.

- Take a clean damp cloth and wipe it around the door sill to free up any build up of sludge that can be caused by moisture from the machine and chemical residue.

- If you have a manual water softener fitted to the machine, ensure that this is salted and regenerated at least once a week to keep on top of unsightly and harmful limescale build up.

- Close your machine down fully each day at the end of a session and ensure you leave the door ajar slightly so that the machine interior is allowed to ‘breathe’ to prevent a musty smell coming from the machine and transferring onto your glassware.

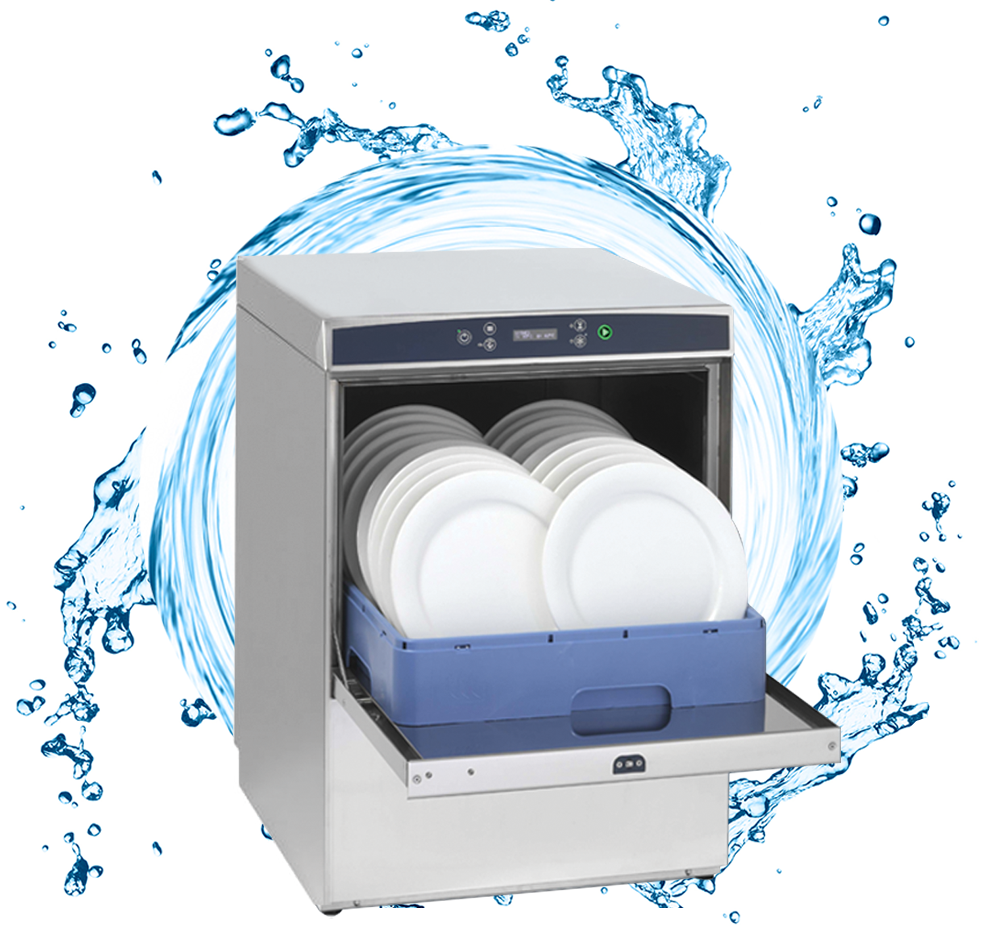

Regent Dishwashers

What is the Regent Range?

Brand new to the Clenaware family is the Regent range of dishwashers, a collection of robust, quality machines constructed from stainless steel and built to keep up with your busy kitchen. Included in the range are under-counter cabinet machines, which then include entry-level versions and premium versions. No matter your choice of machine, you can guarantee an excellent wash result with the unique PRS (Premium Rinse System). All of the Regent machines are fully WRAS approved and include a type A air gap.

What is the PRS (Premium Rinse System)?

For an accurately monitored rinse and outstanding results with zero waste, all of the Regent Dishwashers utilise PRS. The PRS oversees every detail of the rinse cycle given the combination of the break tank, the atmospheric boiler and the rinse pump. By using PRS, the dishwasher doesn’t need to rely on the network’s water pressure; it can function perfectly well with just 1 bar! This system guarantees:

- Constant temperature of 84°C throughout the entire rinse cycle avoiding mixing with cold water which occurs in traditional rinse systems.

- Constant output pressure from rinse nozzles and excellent rotation of the rinse arms.

- Optimum consumption of water and chemical products throughout the rinse cycle hence avoiding excess water and product waste.

- Overall sanitisation of the dishes to ensure a high level of hygiene and thorough elimination of residual detergent.

- Fast drying of dishes due to the stable temperature throughout the rinse cycle.

Commercial dishwashers come in a variety of shapes and sizes and depending on the size or type of business you operate will inform your decision on the best type of dishwasher for you.

Undercounter dishwashers are compact and fit well into small to medium size establishments such as cafes, pubs and small restaurants. With their small footprint, they can be positioned wherever they need to be, they are easy to maintain, access and clean and a perfect upgrade to a standard dishwasher that cannot keep up with the requirements of your kitchen.

If you’d like more advice on what type of commercial dishwasher is best suited for your kitchen, get in touch, our experienced team are on hand to provide any information you require to help you make an informed decision.

Gogglewash Range

The Gogglewash range was created to provide services, and wash systems specifically for the care of 3D Glasses used primarily in 3D Cinema, Screening Rooms, Theme Parks, Educational Establishments and other public attractions.

The products in the Gogglewash range include the Gogglewash Machine, Racks and Trolley Units. Which, when used in conjunction with each other, provide excellent results.

Did you know? The unique Gogglewash Machine utalises specialist washing cycles, that are designed to clean your 3D glasses fast and hygienically. That's why Dolby recommends us!

Frequently Asked Questions

Q. How many glasses can the Gogglewash Machine wash in 1 hour?

A. The Gogglewash Machine is capable of washing up to 640 glasses in 1 hour. This is not a maximum theoretical number but what is reasonable to expect

Q. What 3D glasses can be washed in the Gogglewash Machine?

A. The Gogglewash Machine has various special wash programmes depending on the type of 3D glasses being washed. We have set programmes for CAT 832 and CAT 834 Dolby 3D glasses as well as XpanD X101 3D Glasses

Q. Is the Gogglewash Machine expensive to operate?

A. The Gogglewash Machine uses minimal amounts of water and detergents. The Initial fill of the machine is only 3.5 Litres of water and then it uses 3.5 Litres per wash. The Detergent usage is only 15.22ml per cycle and Rinse Aid 1.58ml per cycle. Average energy consumption per cycle is only 4.14kWh

Q. What water supply does the Gogglewash Machine need?

A. The machine requires either a cold water or hot water supply. The water pressure can be as low as 0.5bar so will operate almost anywhere. The hot water supply cannot exceed 60ºC

Q. How hygienic is the Gogglewash Machine?

A. With the use of our specialist chemicals and temperature the Gogglewash Machine provides excellent hygiene. In addition it operates a fresh water wash, which means, unlike a commercial dishwasher, it is not re-using dirty water, so it provides optimum levels of hygiene. When the machine is turned off it completes an automatic wash down procedure which cleans the machine and leaves it clear of water. The benefit of this is that if there are long periods of time between 3D screenings there is no water trapped inside the wash system and fester which is typical of commercial dishwashers.

Q. Is the Gogglewash Machine easy to use?

A. The Gogglewash Machine has very simple soft touch electronic controls. There is a simple on/off procedure and then just a cycle start switch for the operator to select when they ware ready to start a cycle.

Tips To Help Look After Your Gogglewash Machine

- Follow the daily cleaning maintenance schedule as listed on the Care Card. Unnecessary dirt build up can cause issues with the working of the machine, such as dirt build up around the Door Frame. This can stop the machine Door Switch activating leading you to believe the machine isn’t working.

- Once you have finished with the machine, select the close down cycle and allow it to complete. Once the cycle is finished, isolate the power to the machine. If you prematurely switch off the machine, the next time you go to use it, it won’t start up correctly.

- In the colder winter months, the water coming into the machine will take longer to heat. So, at the start of the working session have a little patience and DO NOT press any buttons whilst waiting for the machine to heat. If you do press buttons unnecessarily this will ‘confuse’ the machine and it won’t fully operate, leading you to believe the machine has broken down.

- If for any reason you have any 3D glasses break inside the machine, ensure that all of the pieces are removed and make sure all of the Wash Tank Filters are firmly in place as these prevent broken fragments from getting into the pumps.

- Use good quality chemicals in the machine, this not only gives you better wash results but also helps to keep the machine clean. It also stops the detergent and rinseaid indicator lights on the Control Panel from going orange, which can lead you to believe the chemicals aren’t dosing properly.

- If you’re in a hard water area, fitting a water treatment to the machine will prevent breakdowns that can result from limescale build-up inside the machine. Parts such as heating elements and hoses can get ‘caked’ with limescale and become less efficient. Limescale can also build up on 3D glasses and affect their performance and appearance.

The Airack Glass Dryer

Do away with tea towels and simply place your glass basket onto the Airack glass dryer and let it work its magic. By using the Airack Glass Dryer, glasses dry 10 times faster which allows you to use them quickly and pour the perfect pint!

Did you know? After being washed, glasses take up to 40 minutes to dry on a ventilated shelf. On the Airack they take as little as 4 minutes! There is no other product like it, why? Because we invented the idea!

Tips For Looking After And Using Your Airack

- Follow the daily maintenance as per the Care Card enclosed with the Airack.

- Make sure you site the Airack correctly as per the Installation Card enclosed with the Airack.

- When the Airack is not in use, disconnect it from the mains supply and remove the Top Cover from the base for cleaning.

- Only clean the Top Cover of the Airack with a clean, damp cloth. Pay attention to the air holes in case of any blockages from water residue, that may otherwise restrict the airflow when the Airack is in use.

- For best results use your Airack with a wire basket as these have bigger clearance holes allowing the air to circulate more freely.

Water Treatments

Over time, fat deposits (fog), limescale and other minerals can begin to build-up on the surfaces of your glass/tableware. This isn’t just unsightly, it’s also another factor preventing the delivery of perfect results. Contaminates and scale found in water can’t always be removed, and these contaminates will ultimately flatten and effect the appearance of drinks. Water treatments are not only beneficial, they are also necessary for delivering perfect results.

How To Spot When Your Calcium Treatment Unit Needs An Exchange

- Wash Results - You will notice spotting or a milky type residue on the glasses after they have been washed in the glasswasher.

- Wash / Rinse Arms - The black plastic of the arms begin to look grey and chalky.

- Wash / Rinse Jets - The small holes in the Wash and Rinse Jets become blocked with limescale and will usually cause issues with the rotation of the arm and cause the rotation light to be red.

- Draining - If there is extra water in the machine and it isn’t draining fully, it is most likely that the Filters inside the Wash Tank are full of limescale or debris, or the Outlet Hose or Drain Pump is full of limescale or debris. If the machine is constantly trying to drain it is likely the Spindles piston (located in the Wash Tank under the Wash Arm) is stuck up due to limescale. This can be resolved by using descaler but can also indicate the CTU is ready for exchange.

- Beer Presentation - The beer isn’t retaining its head, or the beer tastes flat. This usually indicates either limescale build up on the glass or can be chemical residue clinging to the limescale build up on the glass.

Chemicals

High quality chemicals are essential for cleaning and drying glasses and tableware, they are also essential for renovating glasses and for looking after your glasswasher/dishwasher. Chemicals play an important part in the overall processes of achieving perfect results.

Did you know? Good quality chemicals are formulated to cope with high levels of tannins, proteins and water hardness, and they aid the drying process by shedding as much excess water from the glass as possible and preventing ‘spotting’.

Why You Should Use High Quality Chemicals

Detergent

- A high quality Detergent is formulated to cope with high levels of tannins, proteins and water hardness.

- Less likely to leave residue on your glasses.

- A low quality Detergent will not clean your glassware. You may find you still have tannins and proteins on the glass making them look dirty and unsightly.

Rinseaid

- A high quality Rinseaid will aid in the drying process by shedding as much excess water from the glass as possible, helping to prevent spotting.

- The Rinseaid we recommend will not ‘froth’ in the Header Tank, unlike other Rinseaids on the market. If you use a lower quality Rinseaid then you may find your machine becomes intermittent and inoperable. This intermittent problem can be due to the Rinseaid frothing in the Header Tank triggering the Float Switch and causing the machine to cut out during the cycle.

Renovate

- Renovating your glassware is essential for removing the manufacturers film on any new glassware.

- Renovating your glassware can help to remove any mineral deposits on the glasses that build up with use over time.

- A low quality Renovate could leave a film on the glass and may cause the beer to go flat.

Chemicals play an important part in the overall process of achieving perfect results.

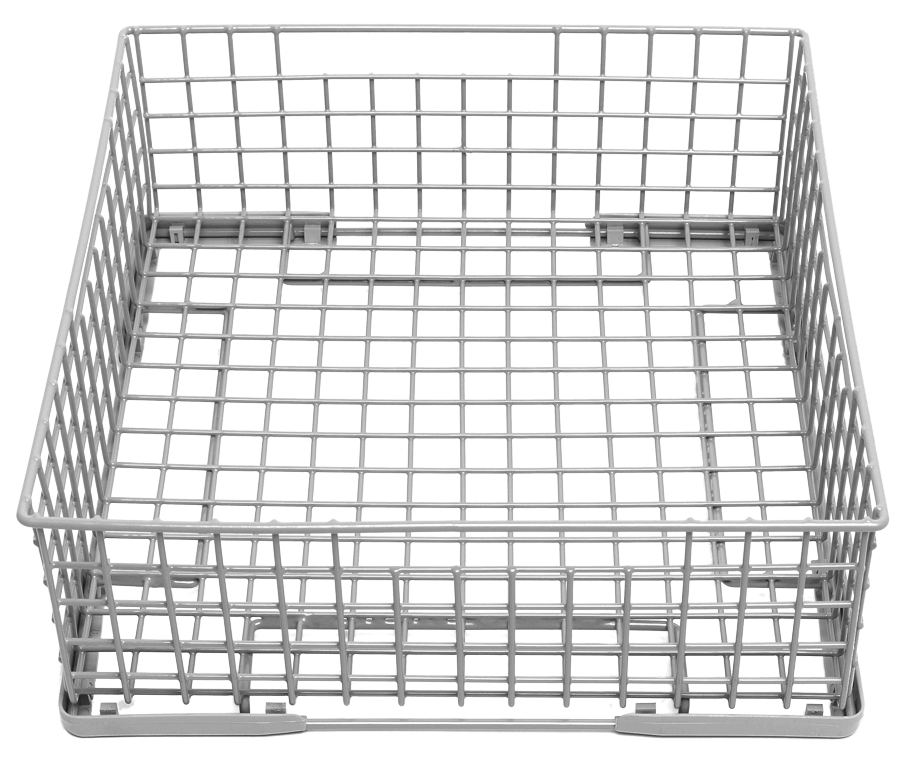

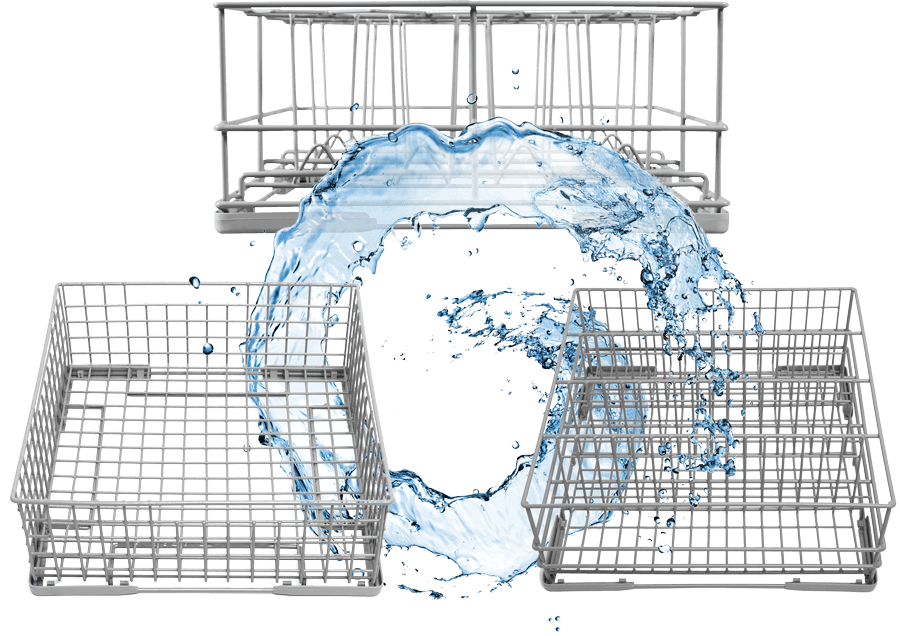

Baskets

With many different styles of glassware in constant use, ensuring you choose the right basket to wash them in is more important than ever. Baskets now come in a range of different sizes and styles, which have been designed specifically with each individual style of glassware in mind.

Did you know? wider spaces between the wirework ensures that the water from the wash and rinse jets have a larger area to get through. This ensures that the glasses are washed and rinsed more thoroughly. This means there’s no escape for grease and dirt!

What are the differences?

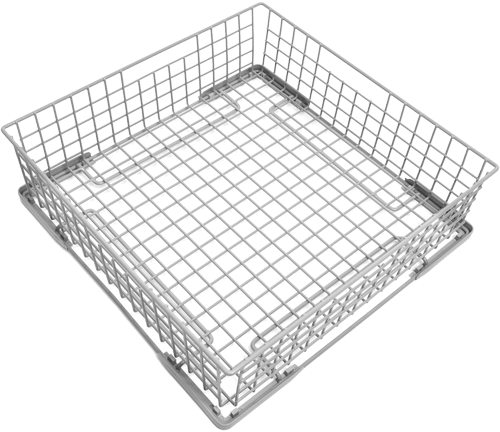

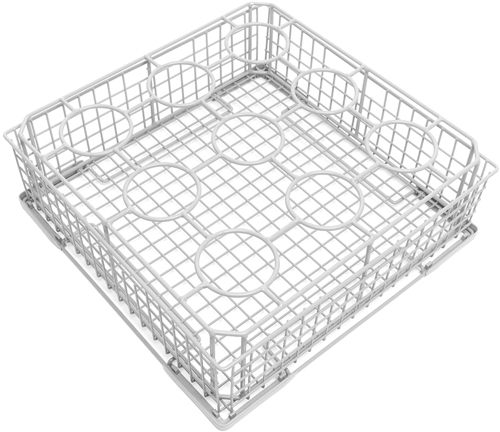

Open Glass Baskets

The Open Glass Basket is suitable for glasses that measure up to 150mm, such as Pint Glasses, Tumbler Glasses, Half Pint Glasses and Hi Ball Glasses. The basket comes with offset hand slots (making it easier to handle) and is coated in a ‘premium’ plastic coating for added hygiene and durability.

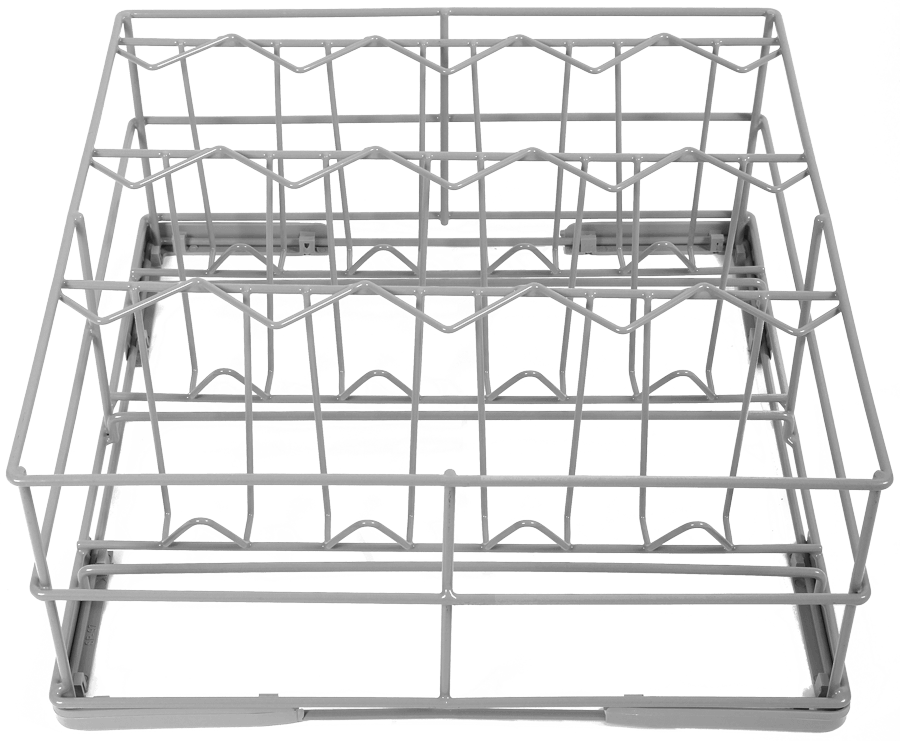

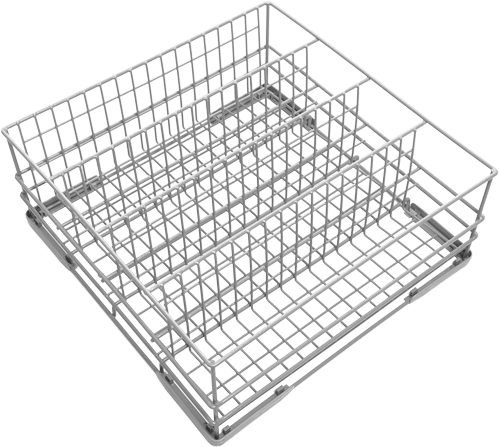

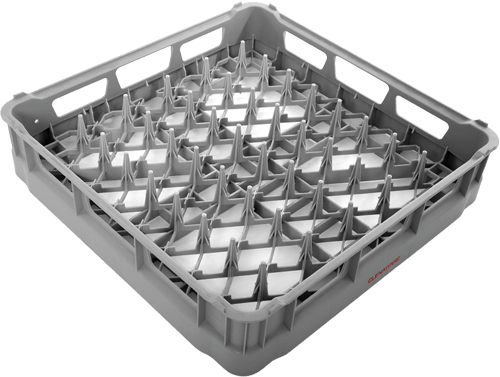

Divided Glass Baskets

The Divided Glass Basket is suitable for specialist style glasses that measure up to 150mm, such as Shot Glasses, Cocktail Glasses, Champagne Glasses and Wine Glasses. The basket is compartmented and angled to aid the drying process and to prevent glass damage.

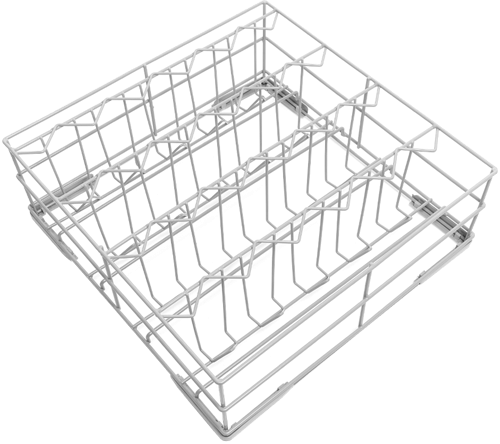

Tall Glass Baskets

The Tall Glass Basket is suitable for Continental style glasses that measure over 150mm in height. This includes glassware such as Pilsner, Peroni and Heineken Glasses. The basket is compartmented and angled to aid with the drying process and also has special glass support inserts to safely accommodate taller glasses.

Half Glass Baskets

The Half Glass Basket has been designed by Clenaware Systems as a versatile basket and has two individual uses. The basket can be used as a glass carrier for staff collecting glasses and has a durable carry handle making it easy and comfortable for staff to carry. The basket can be used in any glasswasher and is ideal when only wanting to wash a small volume of glasses. The basket comes with four corner clips as standard, and is coated with a premium plastic coating for added hygiene and durability.

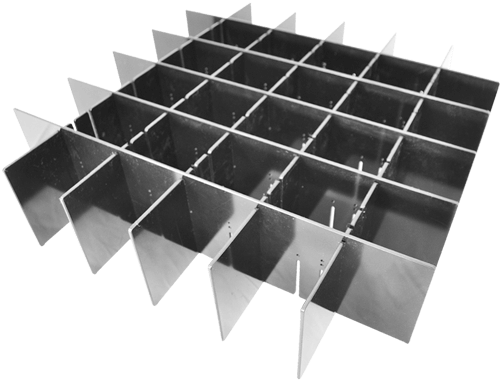

Divider Kits

The basket Divider Kit is suitable for use in a 40, 45 or 50 size glass washing basket. The plastic inserts can be put together in a matrix to make a maximum of 36 compartments allowing you to turn a standard open basket into a more versatile basket, enabling you to wash a number of varied glassware items instead of having to use separate baskets for specific glass styles.

Carafe Insert

The Carafe Insert is used for washing Wine Carafes and Decanters, which in normal standard glass washing baskets would probably topple over resulting not only in breakages but also the Carafes not being thoroughly cleaned. The insert is designed to fit inside a 500mm2 (50 size) basket.

Racks

With many different styles and sizes of tableware in constant use, ensuring you choose the right dishwasher rack to wash them in is more ever. Dishwasher racks come in a range of styles which have been designed with a specific use in mind.

Did you know? The Clenaware Dishwasher racks are suitable not only for your standard tableware, but can also be used to hold specialist items such as chopsticks.

What are the differences?

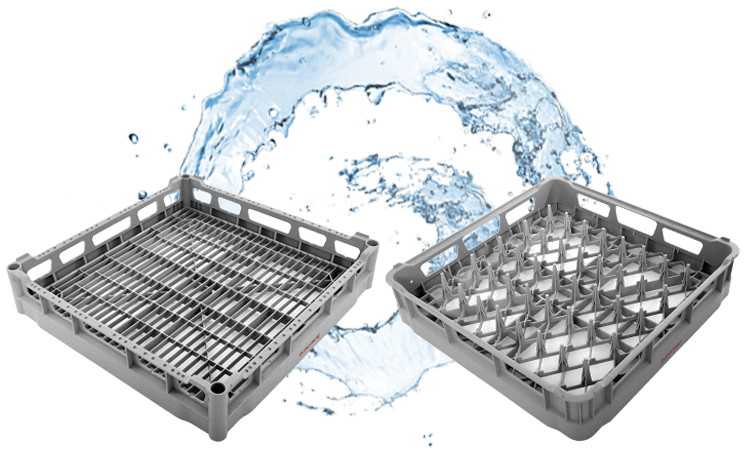

Dish Rack

The dish rack is of a Thermoplastic design, with special support prongs to hold plates and saucers upright, ensuring optimum cleaning whilst in the dishwasher. As the dish rack is compartmented, it is useful for washing a variety of dish sizes in one cycle.

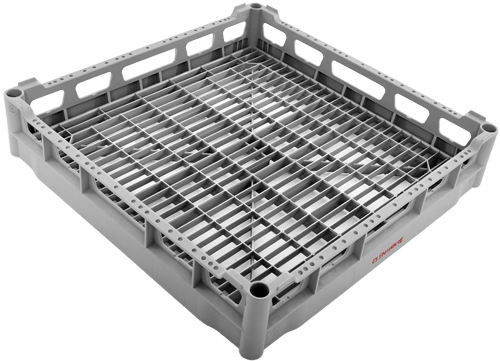

Open Rack

The open rack is of a Thermoplastic design and has a flat, open base. The open area allows for extra utensils and cutlery, or larger items such as whisks or large kitchen knives, that may otherwise not fit into a Cutlery Rack.

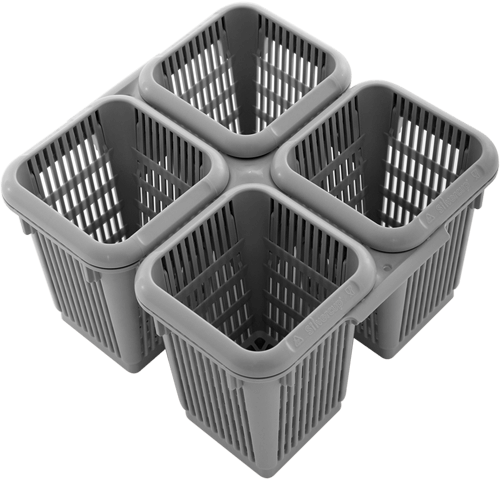

Cutlery Rack

The cutlery rack is a compartmented basket and has a Thermoplastic design. The rack has 4 generous sized compartments for your knives, forks, spoons and other utensils. The cutlery rack sits inside any dishwasher rack, which means you can wash your cutlery with other items such as plates and cups.

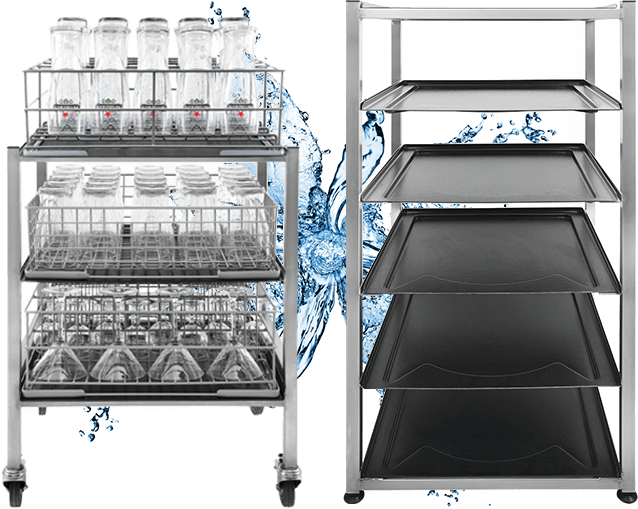

Basket Units

The correct storage of your glass and tableware contributes to the achievement of a perfect result and makes the results safer and more hygienic.

Did you know? By placing clean glass and tableware onto a shelf or in a cupboard, the risk of cross-contamination and dampness is high, resulting in 'musty' smelling glass and tableware as well as tired-looking and flat-tasting drinks.

What are the differences?

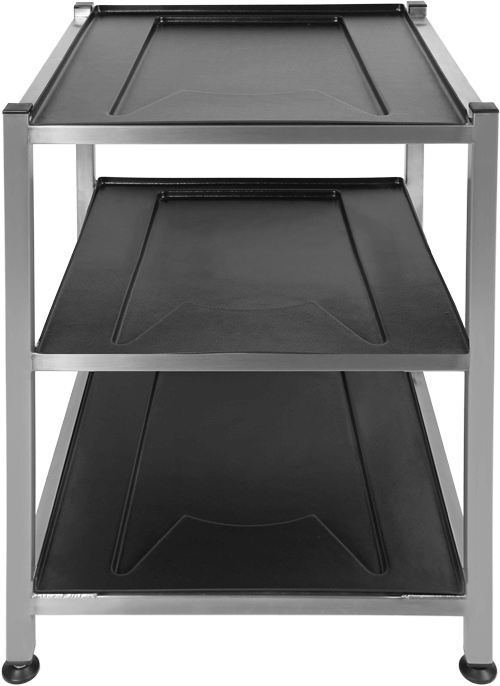

Static Units

Static basket units slide snugly and easily into spare space in the bar area, ideally next to your Glass washer and Airack glass dryer. Static basket units are available as 3 or 5 tier high units.

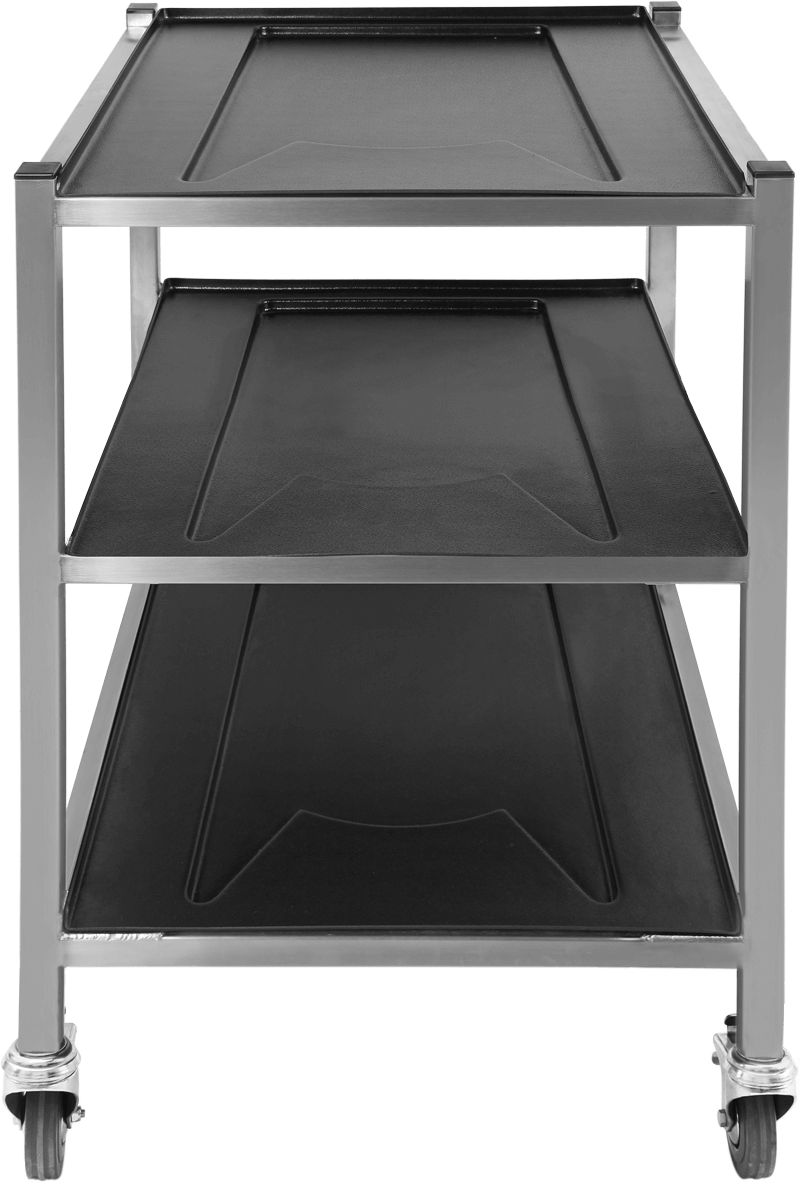

Mobile Units

Mobile Basket Units are designed for easy movement around the bar area. As standard they come with braked castors for safety once the unit is in position for storage. They are available as 3 or 5 tier high units.

Service & Support

At Clenaware we offer a range of service and support packages that ensure the Clenaware experience is the best that it can be for your glasswasher or dishwasher. Clenaware engineers have the skill and knowledge to carry out servicing and repairs to your Clenaware equipment and carry stock of genuine Clenaware parts.

Purchase

For pricing information or if you would like to purchase any Clenaware products, please call us on 01933 666244 and select option 1 for sales. Alternatively, to arrange a call back from one of our team you can email us at sales@clenaware.co.uk. For customers outside of the UK please visit our Contact Us page.

Enquiries

Help and advice on any of our services or products is only a phone call away, please call us on 01933 666244. For sales its option 1 or email sales@clenaware.co.uk For spare parts its option 2 or email spares@clenaware.co.uk For service & support its option 3 or email service@clenaware.co.uk