It appears you are shopping outside of the UK. For orders outside of the UK, please call our sales team on +44 (0) 1933 666 244

Free next-day delivery is an online promotion; orders placed over the phone will be subject to a delivery charge. Orders placed online below £100.00 ex VAT are subject to a delivery charge.

Next-day delivery applies to orders that are placed Monday to Thursday before 1 p.m. for products that are in stock. Orders placed after 1 p.m. will be processed and shipped the next working day.

Orders placed on Friday before 1 p.m. will be shipped for delivery on Monday. Orders placed on Friday after 1 p.m. will be shipped for delivery on Tuesday.

Free shipping is only available to mainland UK (excludes Northern Ireland).

Stock levels can affect delivery times; you will be notified if there are any delays.

10% discount will be applied to your order after sharing your purchase via Facebook, when prompted during the checkout process.

10% discount does not apply to products in which you spread the payment.

10% discount will be applied to your order after sharing your purchase via Facebook, when prompted during the checkout process.

10% discount does not apply to products in which you spread the payment.

At Clenaware Systems, we recognise that in our day to day operations, we inevitably impact on the environment in several ways and are committed to reducing that impact through continual improvement in our environmental performance.

How our products are manufactured through to the final delivery to our customers matters to us. We focus on using our resources efficiently and manage our waste effectively, to impact on the environment as little as possible. At Clenaware Systems, its not just an environmental strategy, its good business.

Clenaware Systems is committed to reducing the impact that our machines and day to day running of the business has on the environment.

Employee awareness towards environmental issues is encouraged and we are committed to reviewing our policy regularly in line with business needs and regulatory requirements. We actively promote the reduce, reuse, recycle philosophy to minimise as best we can the impact that we have on the environment.

All of our manufacturing equipment, office equipment and company vehicles are subject to regular maintenance programmes in order to promote their energy efficiency and therefore keep their impact on the environment to a minimum.

We are registered with the Environment Agency and take great pride in our product design, which allows us to incorporate the environment at the initial design and build right through to the final production and shipping of all our products.

We actively promote the recycling of any waste products produced in both the manufacture of our products and the administration of delivering the products to our customers.

We promote recycling across the business and have a staff training program in place to raise awareness and to enlist their support in improving the recycling that we at Clenaware Systems do. We also encourage the adoption of similar principles by our suppliers.

We provide specific waste skips that are collected by specialist recycling companies to avoid waste going into landfill. All our metal and cardboard waste is sent for recycling on a regular basis.

Our premises are fully equipped with recycling bins for items such as paper and card, plastic, cans and glass. We actively encourage our staff and any visitors to our business to make the right choices when disposing of waste.

The WEEE (Waste Electronic and Electrical Equipment) directive is an EU-wide legislation that obliges electronic and electrical product manufacturers to assume responsibility for their electrical waste. Any products that are covered by WEEE can be identified by the following symbol.

Our WEEE registration number is WEEE/DE2076RU

The crossed-out wheelie bin symbolises that WEEE is required and that any of our equipment is to be disposed of correctly to comply with regulation. The black line underneath the crossed-out wheelie bin states that EEE was manufactured and put on the market on or after 13th August 2005.

At Clenaware Systems we take our responsibilities under the WEEE directive very seriously. If you would like to discuss returning your old Clenaware Systems machine to us under WEEE then please call us on 01933 666244.

The chemicals sold by Clenaware Systems are specifically designed for use in commercial glasswashers and dishwashers. A list of safety data sheets can be provided on request.

Most recently, we have made the move to store our chemicals in smaller bottles also reducing the level of waste produced by our customers when disposing of the empty containers.

Whilst we do not manufacture chemicals ourselves, we continue to work with our suppliers to understand the impact of the REACH regulation (Registration, Evaluation, Authorisation and Restriction of Chemicals) on our products and will always take action to ensure that any risks to the environment as a result of using chemicals are reviewed and passed on to our customers and distributors.

We transport our chemicals using specific carriers to reduce the impact on the environment should an incident occur during delivery to our customers.

The Clenaware Systems range of glasswashers and dishwashers are "Fresh Water Wash" machines, meaning the first wash is exactly the same as the last. The "Fresh Water Wash" system replaces the wash water every time and the rinse water is always fresh to ensure that the same consistent wash results are obtained.

The machines do not contain large wash tanks or rinse boilers that hold more water than is required for a single wash cycle. The Clenaware Systems glasswashers and dishwashers only fill with the water required for each wash cycle.

Our Research and Development team continually work to ensure that our machines use the minimum amount of water possible whilst still achieving a consistent "Fresh Water Wash" result.

Our glasswashers also feature a special Renovate cycle which can be run at any time without the need for emptying and re-filling the machine which reduces the amount of water used.

All Clenaware Systems glasswashers and dishwashers are WRAS (Water Regulations Advisory Scheme) approved to eliminate the risk of contamination of water supplies.

Clenaware Systems glasswashers and dishwashers can be wired as a Single Phase 13 Amp or 30 Amp machine.

Each machine is fitted with only the heaters required to operate at the relevant electrical level, reducing the amount of energy required to operate a wash or rinse cycle.

The machines can be connected to either a hot or cold water supply, with hot allowing for less heating in the machine during wash or rinse cycles.

The launch of our new model of the Sovereign glasswasher, incorporates a heat exchange system. This system reduces the heating power required in the machine which in turn lowers power consumption and operating costs.

Our Research and Development team continually work to ensure that our machines use the minimum amount of energy possible each time.

From wash to pour, touch the glass only once. Our essential hygiene guide. Read More

To help find the perfect Airack for you lets start with what you hope to achieve

Whats more important to you?

Understood, time is of the essence!

What glasses are you going to be drying?

Understood, nobody wants a flat looking beer!

What glasses are you going to be drying?

Thank you! Nearly there

What size glass basket do you have?

Oooh, Fancy!

What size glass basket do you have?

It's a match! Based on your answers we reccomend:

Airack Glass Dryer - Lite - 40 Size

The Airack Lite is perfect for your glassware and set up based on your answers. With its mechanical manual runback timer, you can set the desired cycle time depending on the types of glasses you want to dry.

Find Out MoreIt's a match! Based on your answers we reccomend:

Airack Glass Dryer - Lite - 45 Size

The Airack Lite is perfect for your glassware and set up based on your answers. With its mechanical manual runback timer, you can set the desired cycle time depending on the types of glasses you want to dry.

Find Out MoreIt's a match! Based on your answers we reccomend:

Airack Glass Dryer - Lite - 50 Size

The Airack Lite is perfect for your glassware and set up based on your answers. With its mechanical manual runback timer, you can set the desired cycle time depending on the types of glasses you want to dry.

Find Out MoreThank you! Couple more questions

Can you place your Airack next to a sink or waste pipe?

Thank you! Nearly there

What size glass basket do you have?

Thank you! Nearly there

What size glass basket do you have?

It's a match! Based on your answers we reccomend:

Airack Glass Dryer - Standard - 40 Size

The Airack Standard is perfect for your glassware and set up based on your answers. This Airack comes with a four-minute electronic timer that automatically shuts off after the cycle. This Airack also comes with a drain funnel tube for the removal of excess water and a changeable airflow filter pad.

Find Out MoreIt's a match! Based on your answers we reccomend:

Airack Glass Dryer - Standard - 45 Size

The Airack Standard is perfect for your glassware and set up based on your answers. This Airack comes with a four-minute electronic timer that automatically shuts off after the cycle. This Airack also comes with a drain funnel tube for the removal of excess water and a changeable airflow filter pad.

Find Out MoreIt's a match! Based on your answers we reccomend:

Airack Glass Dryer - Standard - 50 Size

The Airack Standard is perfect for your glassware and set up based on your answers. This Airack comes with a four-minute electronic timer that automatically shuts off after the cycle. This Airack also comes with a drain funnel tube for the removal of excess water and a changeable airflow filter pad.

Find Out MoreIt's a match! Based on your answers we reccomend:

Airack Glass Dryer - Lite - 40 Size

The Airack Lite is perfect for your glassware and set up based on your answers. With its mechanical manual runback timer, you can set the desired cycle time depending on the types of glasses you want to dry.

Find Out MoreIt's a match! Based on your answers we reccomend:

Airack Glass Dryer - Lite - 45 Size

The Airack Lite is perfect for your glassware and set up based on your answers. With its mechanical manual runback timer, you can set the desired cycle time depending on the types of glasses you want to dry.

Find Out MoreIt's a match! Based on your answers we reccomend:

Airack Glass Dryer - Lite - 50 Size

The Airack Lite is perfect for your glassware and set up based on your answers. With its mechanical manual runback timer, you can set the desired cycle time depending on the types of glasses you want to dry.

Find Out MoreOkay, lets get started!

What glasses are you washing?

Thank you! Nearly there

What size glasswasher / basket do you have?

Thank you! Nearly there

What size glasswasher / basket do you have?

Thank you! Nearly there

What size glasswasher / basket do you have?

Thank you! Nearly there

What size glasswasher / basket do you have?

It's a match! Based on your answers I recommend:

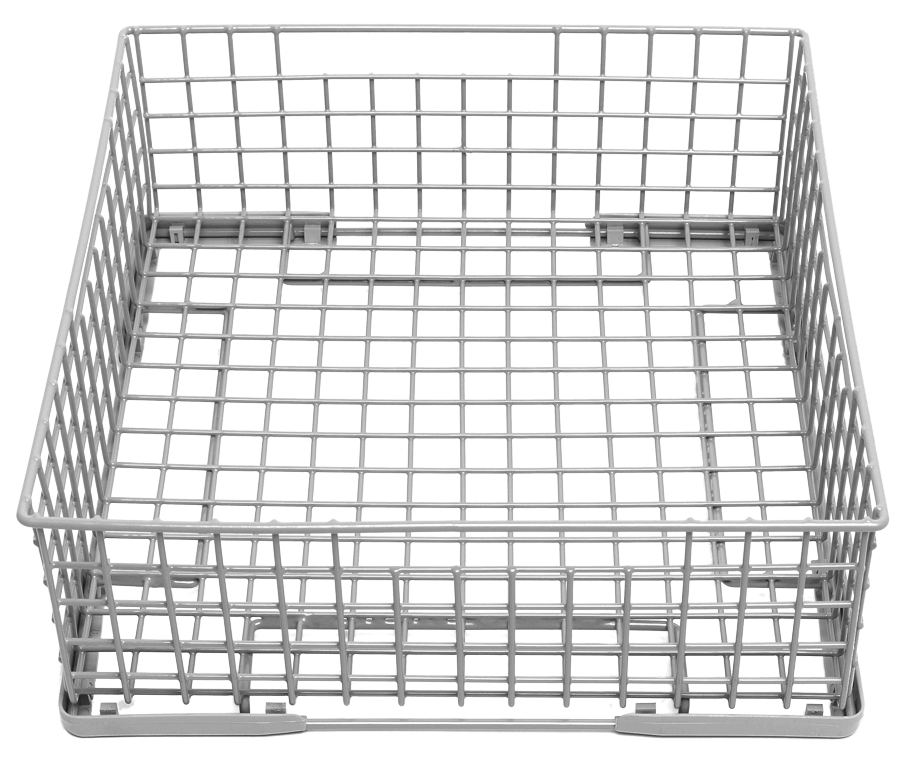

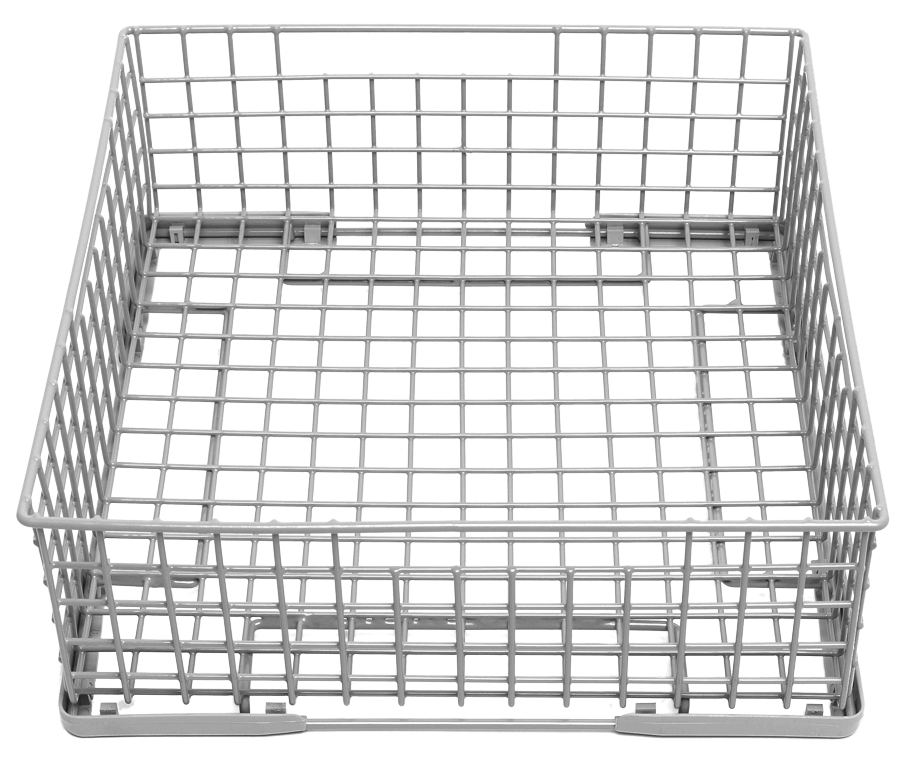

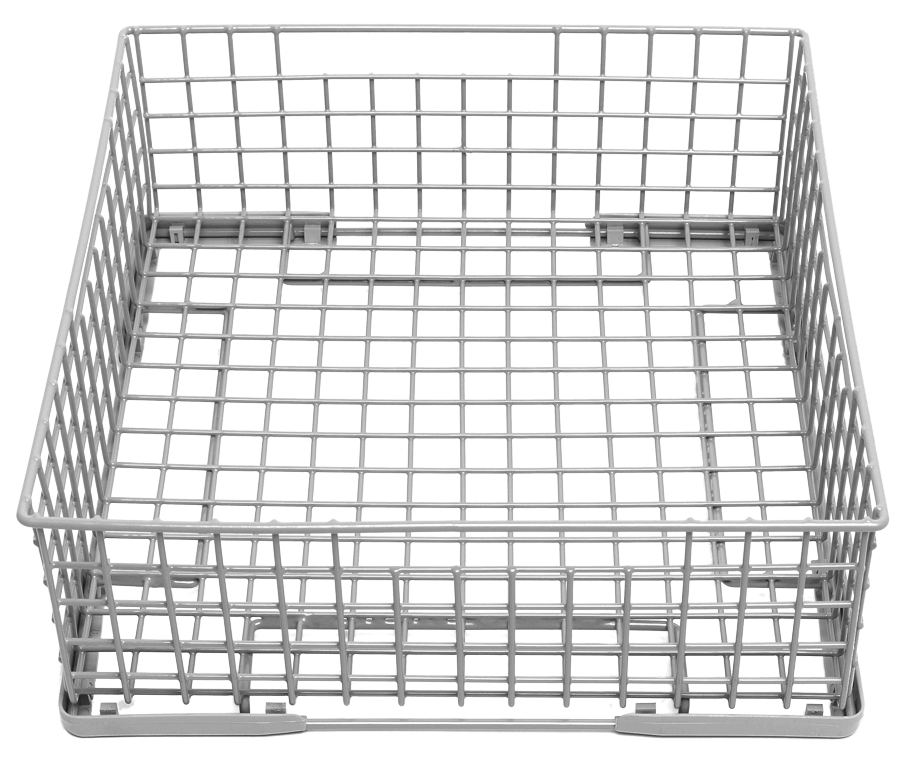

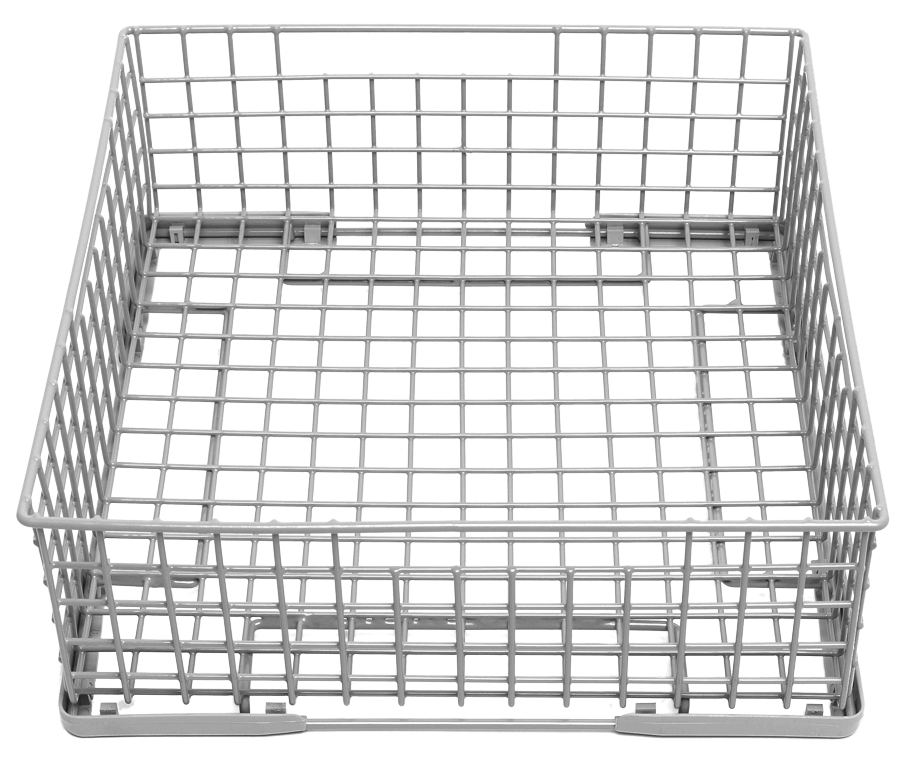

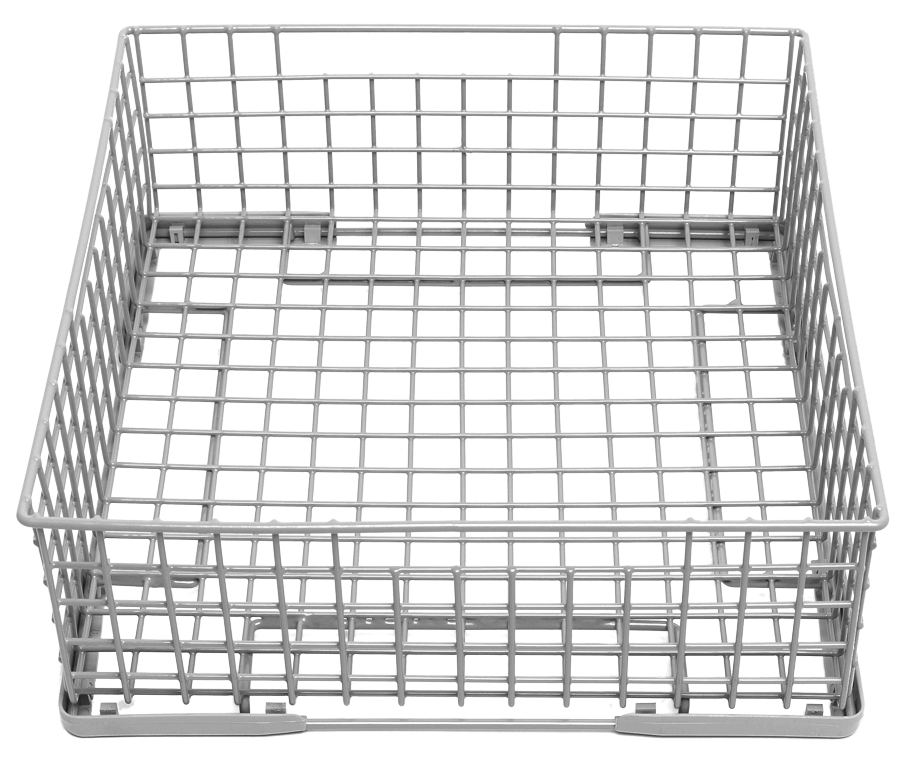

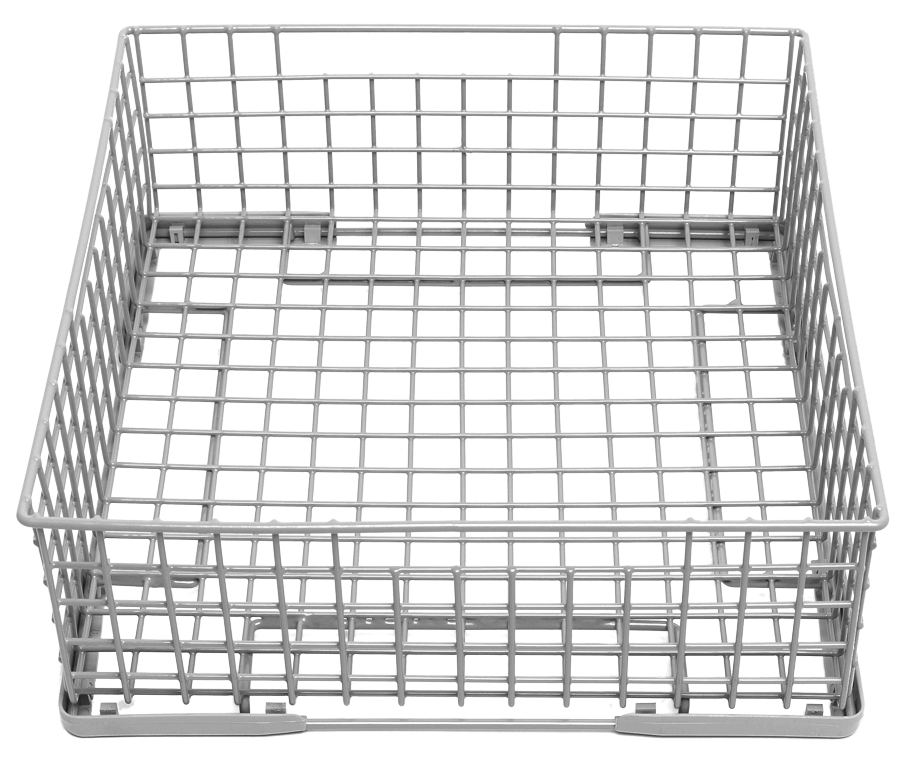

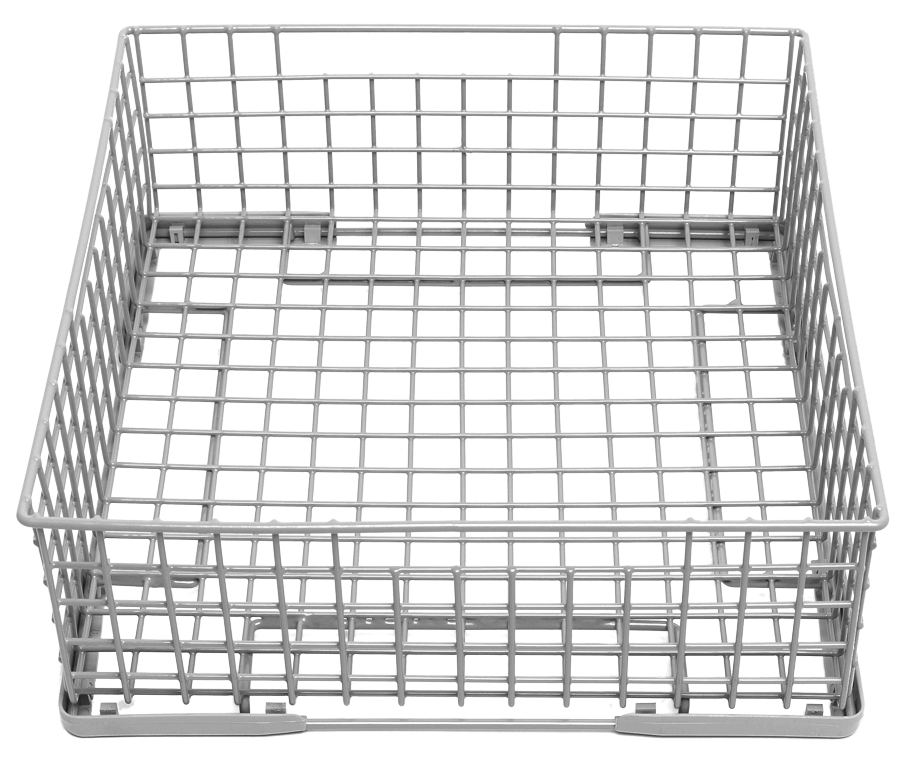

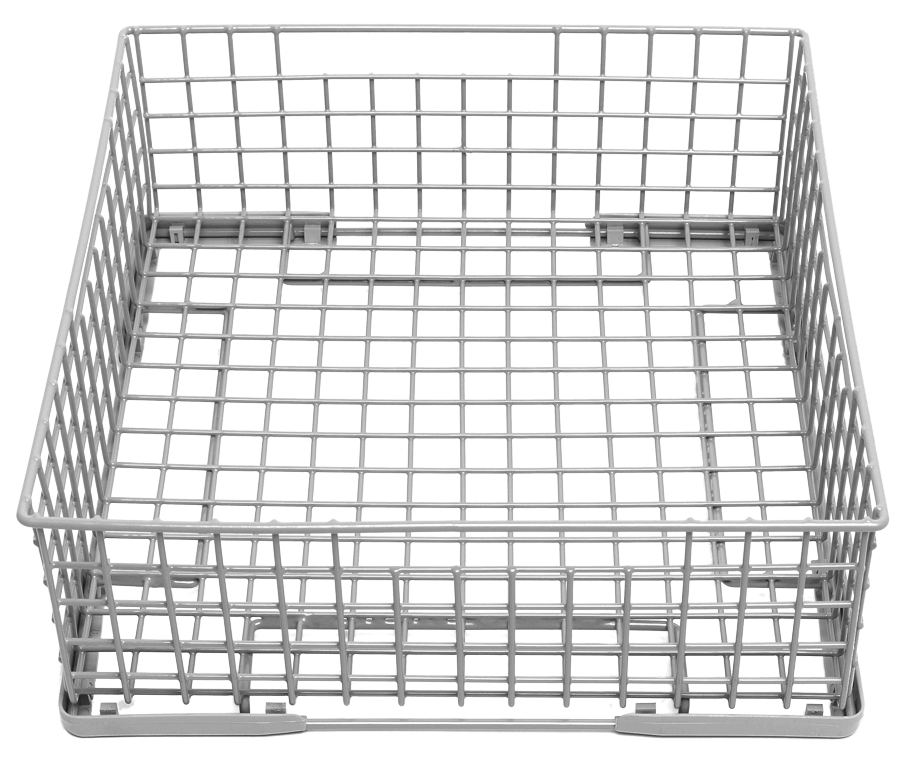

Glass Basket - SOV 40 - Premium

The Open Glass Basket is suitable for glasses that measure up to 150mm in height, such as Pint Glasses, Tumbler Glasses, Half Pint Glasses and Hi-Ball Glasses. The basket comes with offset hand slots which make it easier to handle and transport. This Open Glass Basket can be used in any 40 size glasswasher.

Find Out MoreIt's a match! Based on your answers I recommend:

Glass Basket - SOV 45 - Premium

The Open Glass Basket is suitable for glasses that measure up to 150mm in height, such as Pint Glasses, Tumbler Glasses, Half Pint Glasses and Hi-Ball Glasses. The basket comes with offset hand slots which make it easier to handle and transport. This Open Glass Basket can be used in any 45 size glasswasher.

Find Out MoreIt's a match! Based on your answers I recommend:

Glass Basket - SOV 50 - Premium

The Open Glass Basket is suitable for glasses that measure up to 150mm in height, such as Pint Glasses, Tumbler Glasses, Half Pint Glasses and Hi-Ball Glasses. The basket comes with offset hand slots which make it easier to handle and transport. This Open Glass Basket can be used in any 50 size glasswasher.

Find Out MoreIt's a match! Based on your answers I recommend:

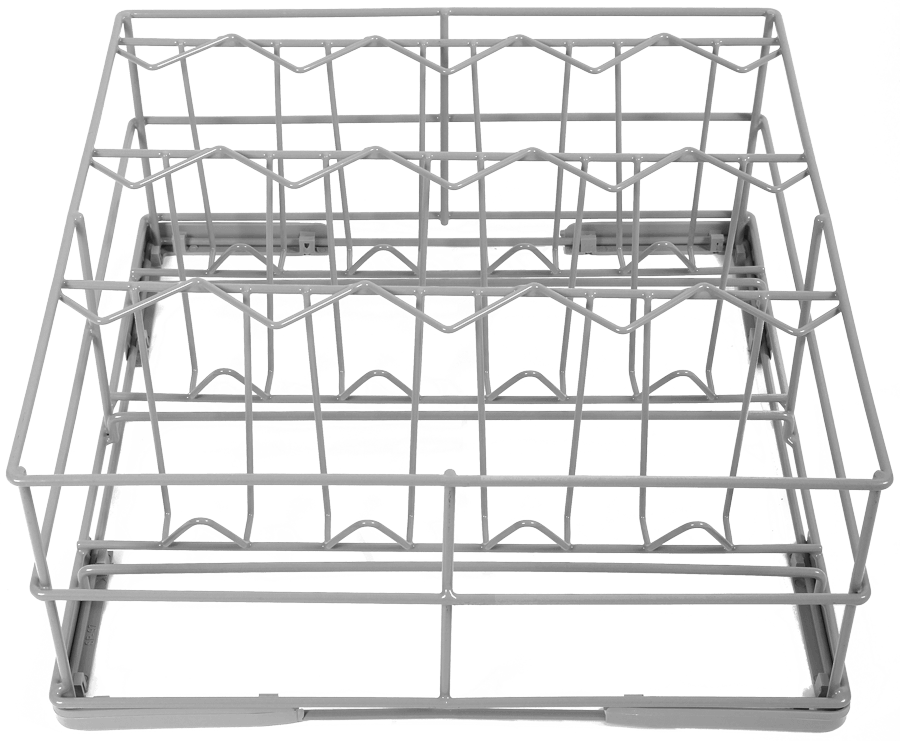

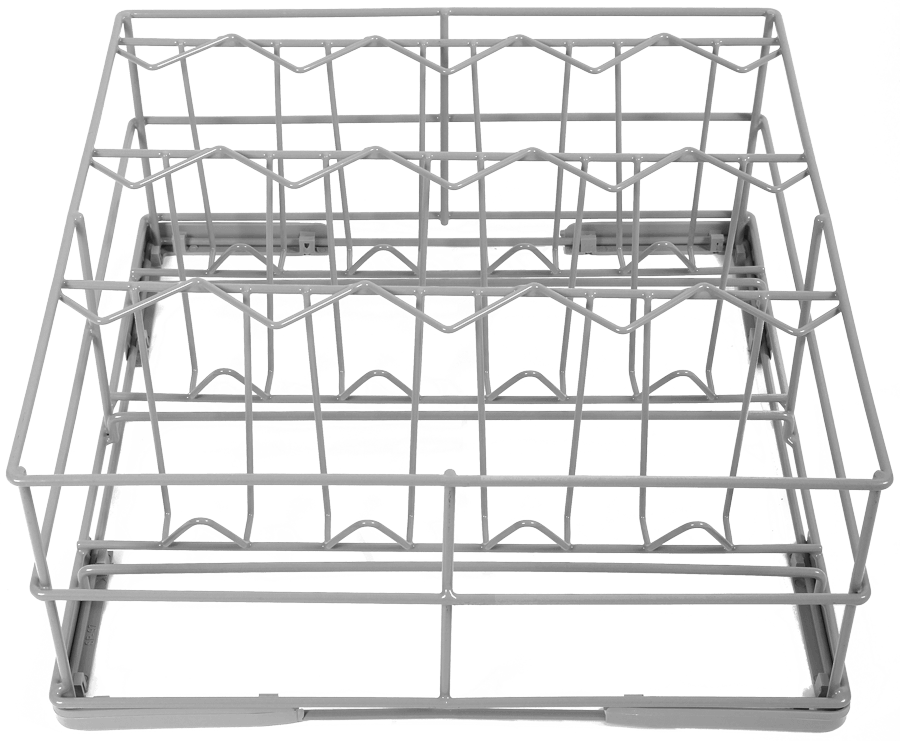

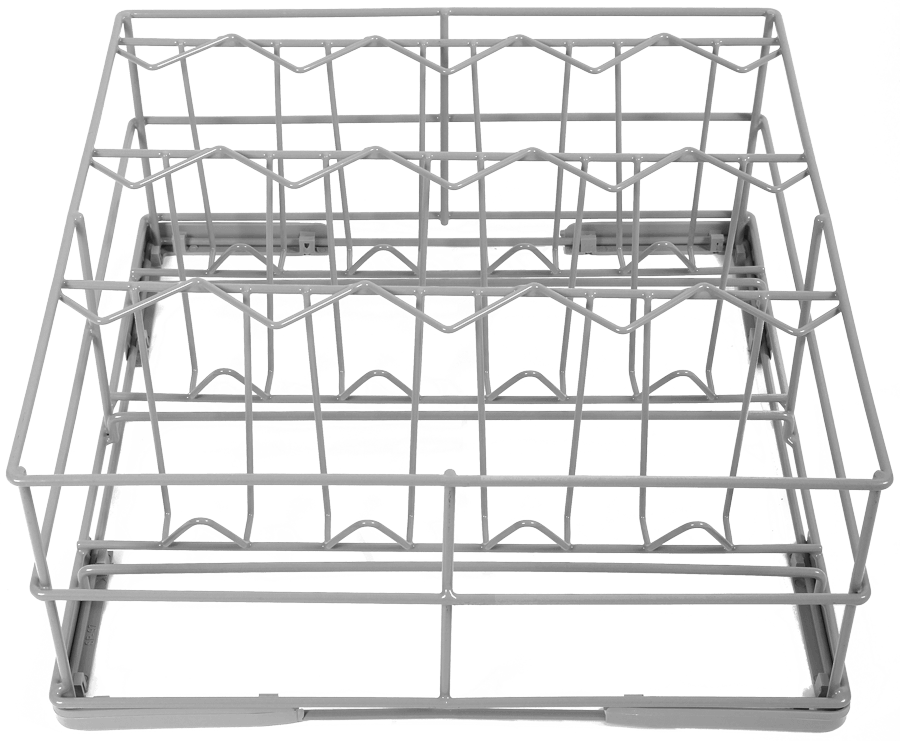

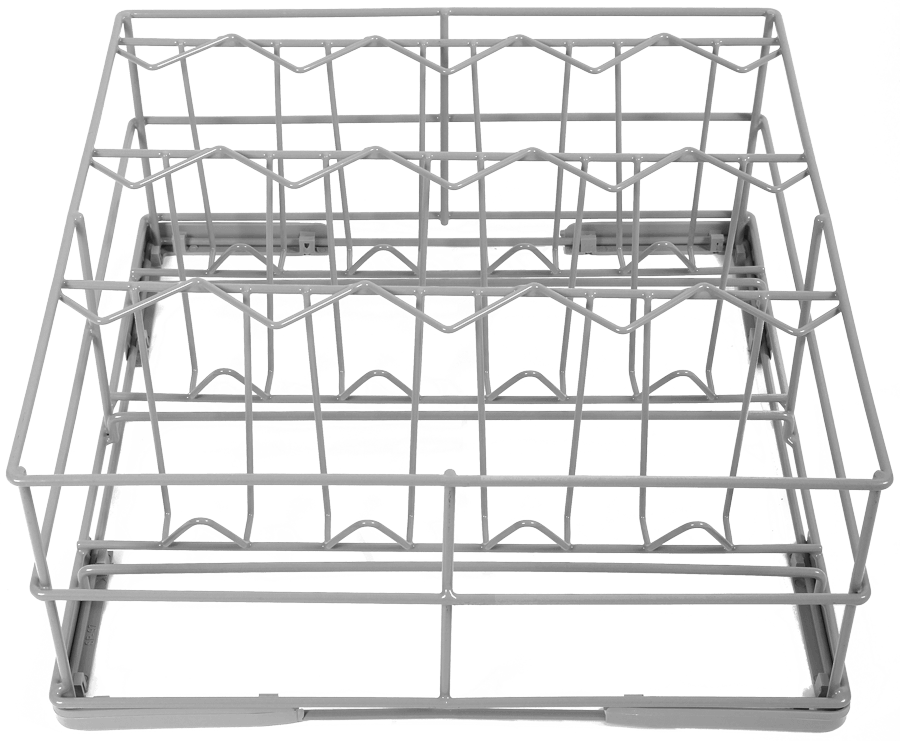

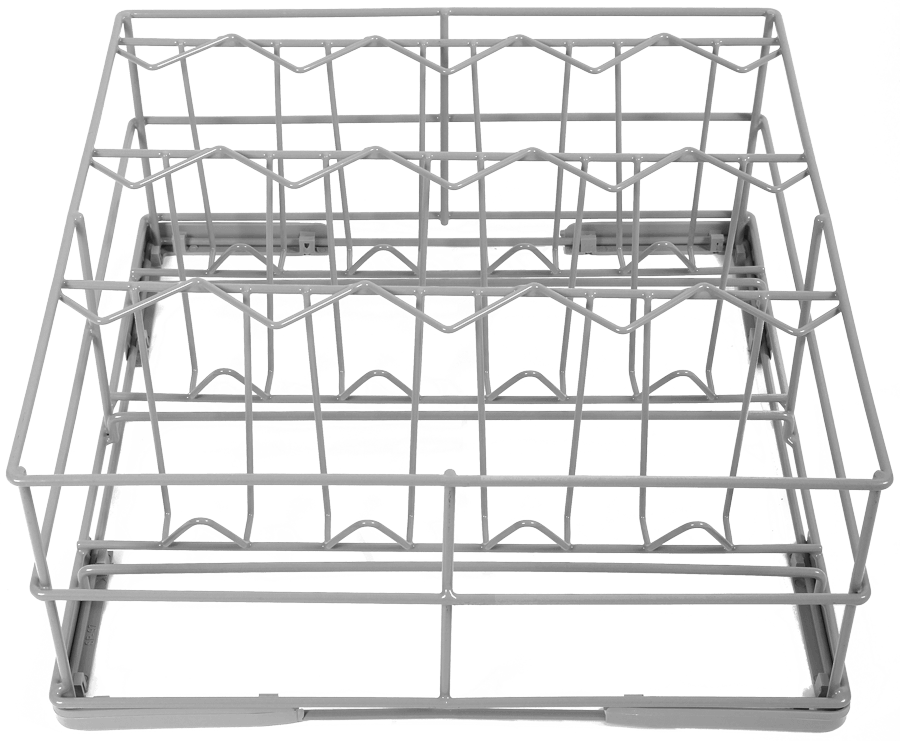

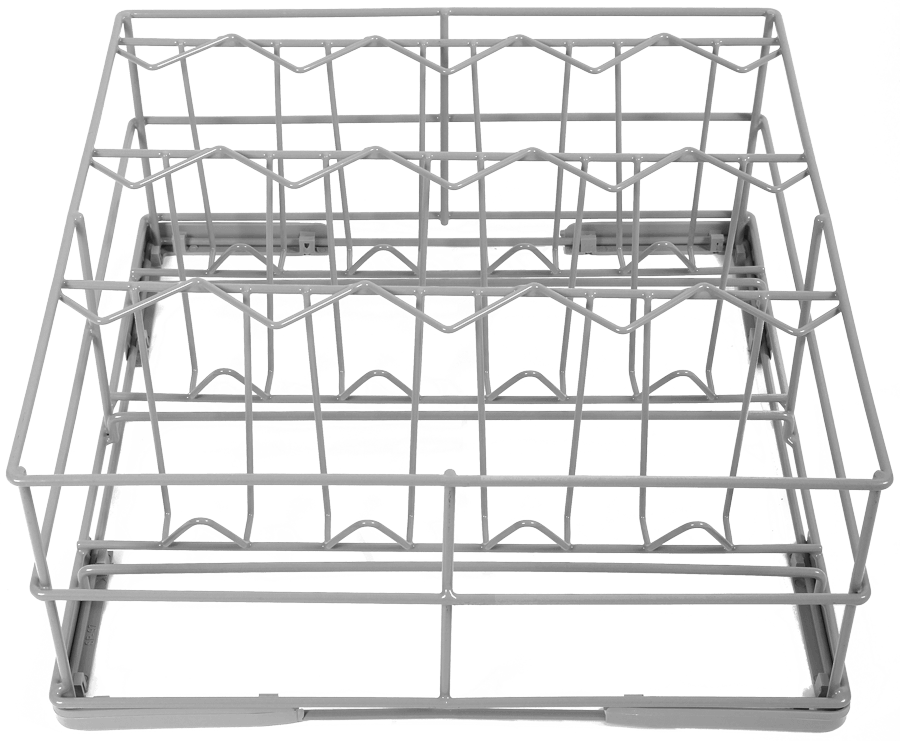

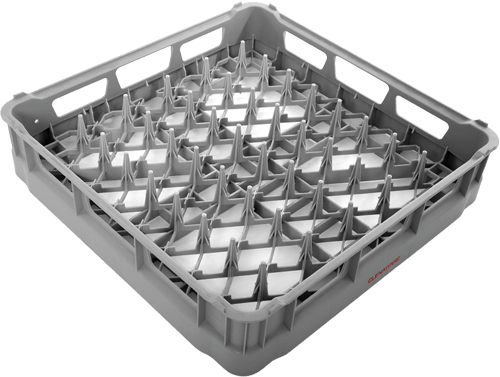

Divided Basket - SOV 40 - Premium

The Divided Glass Basket is suitable for specialist style glasses that measure up to 150mm in height, such as Shot Glasses, Cocktail Glasses, Champagne Glasses and Wine Glasses. The basket is compartmented and angled to aid the drying process and to prevent glass damage or breakages. This Divided Glass Basket can be used in any 40 size glasswasher.

Find Out MoreIt's a match! Based on your answers I recommend:

Divided Basket - SOV 45 - Premium

The Divided Glass Basket is suitable for specialist style glasses that measure up to 150mm in height, such as Shot Glasses, Cocktail Glasses, Champagne Glasses and Wine Glasses. The basket is compartmented and angled to aid the drying process and to prevent glass damage or breakages. This Divided Glass Basket can be used in any 45 size glasswasher.

Find Out MoreIt's a match! Based on your answers I recommend:

Divided Basket - SOV 50 - Premium

The Divided Glass Basket is suitable for specialist style glasses that measure up to 150mm in height, such as Shot Glasses, Cocktail Glasses, Champagne Glasses and Wine Glasses. The basket is compartmented and angled to aid the drying process and to prevent glass damage or breakages. This Divided Glass Basket can be used in any 50 size glasswasher.

Find Out MoreIt's a match! Based on your answers I recommend:

Tall Glass Basket - SOV 40 - Premium

The Tall Glass Basket is suitable for 'Continental' style glasses that measure over 150mm in height. This includes glassware such as Pilsner glasses, Heineken and Peroni glasses. This Glass Basket has been designed with compartments and angled to aid in the drying process and also has special support inserts which sit inside the glasses. The support insert, safely accommodates the taller style glasses from falling over in the glasswasher which can cause damage to the glassware. This Tall Glass Basket can be used in any 40 size glasswasher.

Find Out MoreIt's a match! Based on your answers I recommend:

Tall Glass Basket - SOV 45 - Premium

The Tall Glass Basket is suitable for 'Continental' style glasses that measure over 150mm in height. This includes glassware such as Pilsner glasses, Heineken and Peroni glasses. This Glass Basket has been designed with compartments and angled to aid in the drying process and also has special support inserts which sit inside the glasses. The support insert, safely accommodates the taller style glasses from falling over in the glasswasher which can cause damage to the glassware. This Tall Glass Basket can be used in any 45 size glasswasher.

Find Out MoreIt's a match! Based on your answers I recommend:

Tall Glass Basket - SOV 50 - Premium

The Tall Glass Basket is suitable for 'Continental' style glasses that measure over 150mm in height. This includes glassware such as Pilsner glasses, Heineken and Peroni glasses. This Glass Basket has been designed with compartments and angled to aid in the drying process and also has special support inserts which sit inside the glasses. The support insert, safely accommodates the taller style glasses from falling over in the glasswasher which can cause damage to the glassware. This Tall Glass Basket can be used in any 50 size glasswasher.

Find Out MoreBased on your answers I recommend:

Glass Basket - SOV 40 - Premium

However, to achieve perfect results and reduce damage to glasses consider sorting your glasses into specific baskets specially designed for each type of glass

This basket comes with offset hand slots which make it easier to handle and transport. This Open Glass Basket can be used in any 40 size glasswasher.

Want to get perfect results?Based on the fact you are washing various items, it would be best to split your glasses into the following baskets:

Standard Glasses

Wine & Cocktail Glasses

Tall Glasses

Based on your answers I recommend:

Glass Basket - SOV 45 - Premium

However, to achieve perfect results and reduce damage to glasses consider sorting your glasses into specific baskets specially designed for each type of glass

This basket comes with offset hand slots which make it easier to handle and transport. This Open Glass Basket can be used in any 45 size glasswasher.

Want to get perfect results?Based on the fact you are washing various items, it would be best to split your glasses into the following baskets:

Standard Glasses

Wine & Cocktail Glasses

Tall Glasses

Based on your answers I recommend:

Glass Basket - SOV 50 - Premium

However, to achieve perfect results and reduce damage to glasses consider sorting your glasses into specific baskets specially designed for each type of glass

This basket comes with offset hand slots which make it easier to handle and transport. This Open Glass Basket can be used in any 50 size glasswasher.

Want to get perfect results?Based on the fact you are washing various items, it would be best to split your glasses into the following baskets:

Standard Glasses

Wine & Cocktail Glasses

Tall Glasses

Okay, lets get started!

What are you washing in your dishwasher?

It's a match! Based on your answers I recommend:

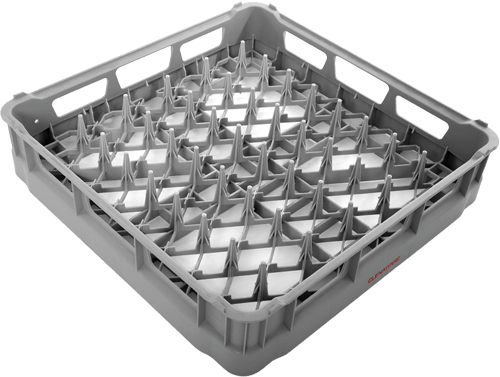

Dish Rack - SDTD

Crockery needs to be loaded into specially designed baskets to keep them in place and allow hot water and chemicals to pass over them to wash them effectively. The Dish Rack is of Thermoplastic design, with special support prongs to hold plates and saucers upright, ensuring optimum cleaning while in the dishwasher. The Dish Rack is suitable for most commercial dishwashers that take a basket up to 500mm.

Find Out MoreIt's a match! Based on your answers I recommend:

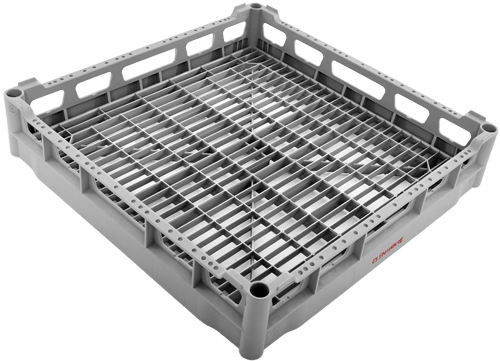

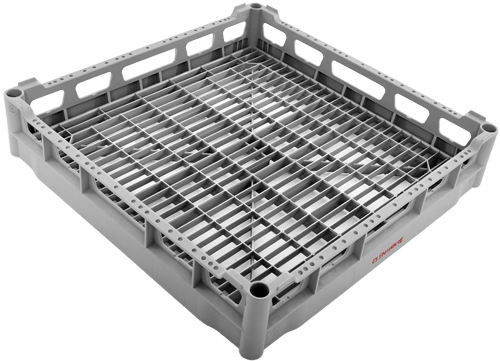

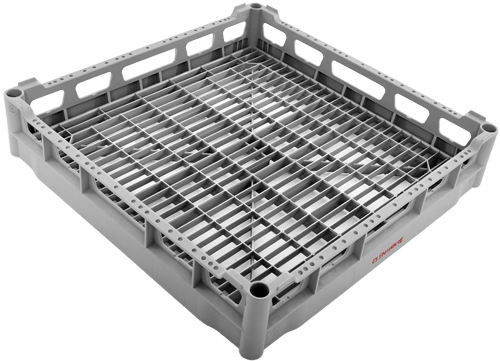

Open Rack - SDTD

The Open Dish Rack is of Thermoplastic design and has a flat open base, making it possible to stack plates, bowls and other dishwasher items. The Open Rack is suitable for most commercial dishwashers that take a basket up to 500mm.

Find Out MoreIt's a match! Based on your answers I recommend:

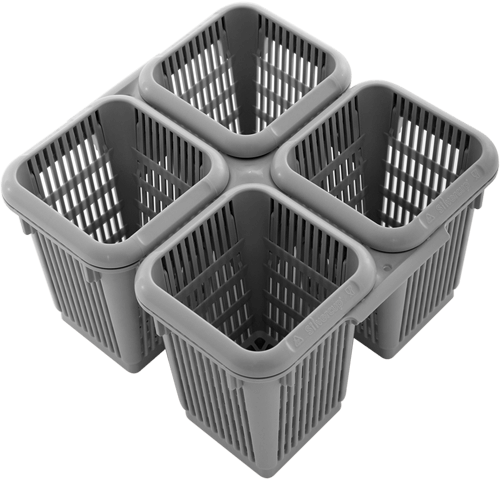

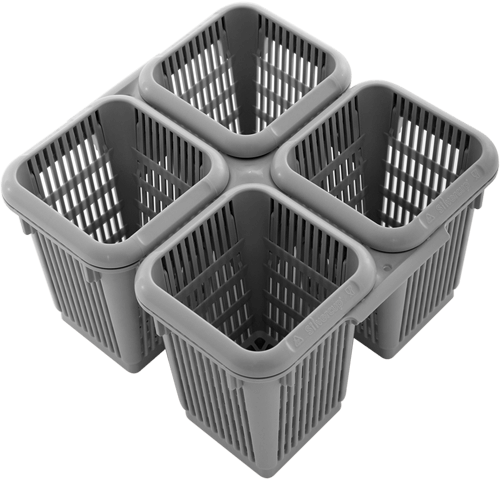

Cutlery Rack - SDTD

The Cutlery Rack is a compartmented basket and has a Thermoplastic design, making it durable. The rack has four generous sized compartments for your knives, forks, spoons and other utensils.

Find Out MoreBased on your answers I recommend:

Open Rack - SDTD

However, to achieve perfect results consider sorting your crockery into specific racks specially designed for each type of crockery

The Open Dish Rack is of Thermoplastic design and has a flat open base, making it possible to stack plates, bowls and other dishwasher items. The open area also allows for extra utensils and cutlery or larger items such as whisks or large kitchen knives that may otherwise not fit into the Cutlery Rack. The Open Rack is suitable for most commercial dishwashers that take a basket up to 500mm.

Want to get perfect results?Based on the fact you are washing various items, it would be best to split your crockery into the following racks:

Plates

Bowls & Mugs

Cutlery

Let's deal with this limescale!

What machine do you have?

Let's protect your glasswasher

What is more important to you?

Let's protect your dishwasher

What type of dishwasher do you have?

Okay, nearly there!

What is more important to you?

It's a match! Based on your answers I recommend:

Manual Water Softener - 12 Ltr

The Manual Water Softener contains resin beads. These beads absorb metal ions found in water (which is commonly calcium and magnesium). The resin contains sodium, hydrogen and potassium, which clean the water by attracting the metal ions to the beads. The softened water then passes from the softener unit and into your machine, giving you better cleaning results and prevents the scale from getting into the essential working parts of your glasswasher.

Find Out MoreUnderstood, You have better things to do than deal with a water softener!

What is more important to you?

Thank you, final question I promise!

Is you machine filling from a hot or cold water feed?

It's a match! Based on your answers I recommend:

Non-Electric Automatic Water Softener - Hot & Cold

Powered by the kinetic energy of moving water this Non-Electric Automatic Water Softener is a high-performance system, specially designed for applications where space is limited. Packed with the latest features and technology, this softener is an ideal choice for use with any commercial warewashing machine, be it on a cold or hot water feed.

Find Out MoreNeed something a little smaller? I recommend:

Compact Non-Electric Automatic Water Softener - Hot & Cold

Boasting the same benefits as its bigger cousin, this Compact Non-Electric Automatic Water Softener has a small footprint but big results. Packed with the latest features and technology, this softener is an ideal choice for use with any commercial warewashing machine, be it on a cold or hot water feed.

Find Out MoreIt's a match! Based on your answers I recommend:

Automatic Water Softener - 10 Ltr - Hot

The Automatic Water Softener as apposed to the Manual Water Softener will not need to be manually regenerated. Controlled by a timer control valve, Ion-Exchange Resin is flushed with a brine solution to recharge at a set time. This is ideal for busy sites with fixed operating times. The Automatic Water Softener requires a salt top-up, usually once a week.

Find Out MoreIt's a match! Based on your answers I recommend:

Automatic Water Softener - 10 Ltr - Cold

The Automatic Water Softener as apposed to the Manual Water Softener will not need to be manually regenerated. Controlled by a timer control valve, Ion-Exchange Resin is flushed with a brine solution to recharge at a set time. This is ideal for busy sites with fixed operating times. The Automatic Water Softener requires a salt top-up, usually once a week.

Find Out MoreOkay, nearly there!

What is more important to you?

Thank you, final question I promise!

Is you machine filling from a hot or cold water feed?

It's a match! Based on your answers I recommend:

Automatic Water Softener - 16 Ltr - Hot

The Automatic Water Softener as apposed to the Manual Water Softener will not need to be manually regenerated. Controlled by a timer control valve, Ion-Exchange Resin is flushed with a brine solution to recharge at a set time. This is ideal for busy sites with fixed operating times. The Automatic Water Softener requires a salt top-up, usually once a week.

Find Out MoreIt's a match! Based on your answers I recommend:

Automatic Water Softener - 16 Ltr - Cold

The Automatic Water Softener as apposed to the Manual Water Softener will not need to be manually regenerated. Controlled by a timer control valve, Ion-Exchange Resin is flushed with a brine solution to recharge at a set time. This is ideal for busy sites with fixed operating times. The Automatic Water Softener requires a salt top-up, usually once a week.

Find Out MoreIt's a match! Based on your answers I recommend:

Non-Electric Automatic Water Softener - Hot & Cold

Powered by the kinetic energy of moving water this Non-Electric Automatic Water Softener is a high-performance system, specially designed for applications where space is limited. Packed with the latest features and technology, this softener is an ideal choice for use with any commercial warewashing machine, be it on a cold or hot water feed.

Find Out MoreNeed something a little smaller? I recommend:

Compact Non-Electric Automatic Water Softener - Hot & Cold

Boasting the same benefits as its bigger cousin, this Compact Non-Electric Automatic Water Softener has a small footprint but big results. Packed with the latest features and technology, this softener is an ideal choice for use with any commercial warewashing machine, be it on a cold or hot water feed.

Find Out MoreYou are not messing around!

Thats a serious bit of kit

I want to make sure you get the right advice and product information for your machine, so I am going to refer you to our brainy office team. Give them a call, and they will be able to provide the best softener for you.

Get In Contact With UsIt's a match! Based on your answers I recommend:

Manual Water Softener - 12 Ltr

The Manual Water Softener contains resin beads. These beads absorb metal ions found in water (which is commonly calcium and magnesium). The resin contains sodium, hydrogen and potassium, which clean the water by attracting the metal ions to the beads. The softened water then passes from the softener unit and into your machine, giving you better cleaning results and prevents the scale from getting into the essential working parts of your glasswasher.

Find Out MoreUnderstood, You have better things to do than deal with a water softener!

What size glasswasher do you have?

It's a match! Based on your answers I recommend:

Calcium Treatment Unit - 18 Ltr

The Calcium Treatment Unit (CTU) is the ideal partner for your warewasher. The CTU aids the removal of chlorine, limescale and heavy metals such as lead, copper and mercury. There is no salt required for this type of unit, as the special resin in the unit can take up to 11000 litres of water flushing through it before the need to exchange.

+ Did you know we offer an exchange service, where we replace your exhausted CTU with a replenished one for a fraction of the cost of a new unit?

Find Out MoreIt's a match! Based on your answers I recommend:

Calcium Treatment Unit - 23 Ltr

The Calcium Treatment Unit (CTU) is the ideal partner for your warewasher. The CTU aids the removal of chlorine, limescale and heavy metals such as lead, copper and mercury. There is no salt required for this type of unit, as the special resin in the unit can take up to 14000 litres of water flushing through it before the need to exchange.

+ Did you know we offer an exchange service, where we replace your exhausted CTU with a replenished one for a fraction of the cost of a new unit?

Find Out MoreLet's get this ice crystal clear!

What is your Ice Machine capable of?

It's a match! Based on your answers I recommend:

Ice Machine Filter - iX01 - Complete

Ice machines that produce cloudy and poor quality ice are likely in need of a filter. When water turns to ice dissolved minerals in hard water precipitate and coat the working surfaces inside the ice machine, this leads to increased energy costs and inferior ice. It will also lead to a reduction in ice production and eventually lead to equipment breakdown, while chlorine in unfiltered water can add unwanted taste and odours.

Find Out MoreIt's a match! Based on your answers I recommend:

Ice Machine Filter - iX02 - Complete

Ice machines that produce cloudy and poor quality ice are likely in need of a filter. When water turns to ice dissolved minerals in hard water precipitate and coat the working surfaces inside the ice machine, this leads to increased energy costs and inferior ice. It will also lead to a reduction in ice production and eventually lead to equipment breakdown, while chlorine in unfiltered water can add unwanted taste and odours.

Find Out MoreLet's find the perfect ice machine for you!

How would you like to start your search?

We have four types of ice on offer

What ice would you like to produce?

That's okay the world of ice can be confusing

How can I help?

Welcome to ice 101

Below is a brief outline of our ice types, but if you need a bit more information, contact one of our ice nerds.

Often referred to as gourmet ice cubes, this type of ice is produced in our CP range of ice machines. Due to the process in which they are created these solid ice cubes have a high density and are crystal clear and end up purer than the water in which they are made. These cubes are suitable for keeping drinks cool for an extended time frame without watering them down.

Perfect for: whiskeys and scotch, certain cocktails, carbonated drinks.

Often referred to as bullet ice, this type of ice is produced in our CV range of ice machines. The hollow cubes have an extended cooling surface and so are especially suited for the fast cooling of drinks intended for immediate consumption. Their hollow shape makes them easy to crush, so they are ideal for use in many types of cocktails.

Perfect for: mixed drinks, drinking water, certain cocktails, carbonated drinks.

This type of ice is produced in our SG range of ice machines and is created at just below 0°C with 25% residual water. This type of ice is perfect for many uses ranging from food display and presentation to the preparation of numerous cocktails.

Perfect for: cocktails, blending with smoothies, slushes, food displays.

The traditional ice cube, this type of ice is produced on our CQ range of ice machines. This shape melts slowly but cools quickly and is a great general purpose cube. Its low production costs make it the most suitable choice for business that requires a high ice consumption. Due to the fast production rate, this machine only comes in the modular style and requires an ice bin.

Perfect for: mixed drinks, carbonated drinks, whiskey and spirits, drinking water.

We have four types of ice on offer

What ice would you like to produce?

Can I get a copy of the drinks menu please?

What drinks do you serve?

Sounds good

What is more important to you?

Sounds good

What is more important to you?

Yummy!

What is more important to you?

Sounds tasty!

For most cocktails, we recommend our premium Granular Ice

Only the best ice for your drinks

For high-end liquor, we recommend the crystal clear Full Ice Cube

It sounds like we need a universal ice cube

As you are using this ice in many drinks, you will want a machine that can keep up with demand and give you a low running cost.

We recommend the Dice Ice Cube

Let's produce some crystal clear ice!

How much ice do you want to produce in a 24 hour period?

Let's work out your ice consumption

To work out how much ice you want to produce, you need to make a few broad calculations based on averages. If you base your calculations on an average ice consumption of 100g (0.1Kg) per drink per customer, you can then multiply this by the amount of drinks you are serving in an hour and then multiply this by 24 to work out your consumption level. We know it seems complicated so we have created an easy to use calculator which you can launch below.

Remember, these calculations are based on averages and should be tailored to your business.

Top Tip: Give yourself breathing room when choosing your ice machine and don't go for a machine that gives you just enough ice. Ensure you have enough ice to cover your needs accounting for ice melting and customer fluctuations.

Let's produce some crystal clear ice!

How much ice do you want to produce in a 24 hour period?

Okay, I have a couple of choices for you

What sounds best suited for you

Okay, I have a couple of choices for you

What sounds best suited for you

It's a match! Based on your answers I recommend:

Nova Ice Machine - CP 20.6 - Full Ice Cube - 18gr

The CP 20.6 solid cube ice maker is an air-cooled, self-contained, under counter machine that is energy efficient and comprised of a full stainless steel body with foam injected polyurethane insulation to preserve ice quality. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 25 Kg of ice every 24 hours, the CP 20.6 is ideal for pubs, bars and other similar sites which require smaller quantities of ice on demand. The internal ice storage bin can hold a maximum of 6 Kg of ice.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - CP 30.10 - Full Ice Cube - 18gr

The CP 30.10 solid cube ice maker is an air-cooled, self-contained, under counter machine that is energy efficient and comprised of a full stainless steel body with foam injected polyurethane insulation to preserve ice quality. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 30 Kg of ice every 24 hours, the CP 30.10 is ideal for pubs, bars and other similar sites which require smaller quantities of ice on demand. The internal ice storage bin can hold a maximum of 10 Kg of ice.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - CP 50.25 - Full Ice Cube - 18gr

The CP 50.25 solid cube ice maker is an air-cooled, self-contained, under counter machine that is energy efficient and comprised of a full stainless steel body with foam injected polyurethane insulation to preserve ice quality. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 50 Kg of ice every 24 hours, the CP 50.25 is ideal for pubs, bars and other similar sites which require smaller quantities of ice on demand. The internal ice storage bin can hold a maximum of 25 Kg of ice.

Find Out MoreIt's a match! Based on your answers I recommend:

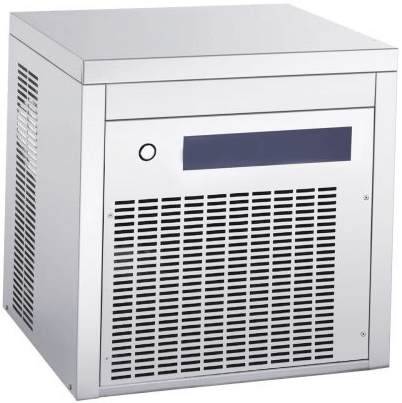

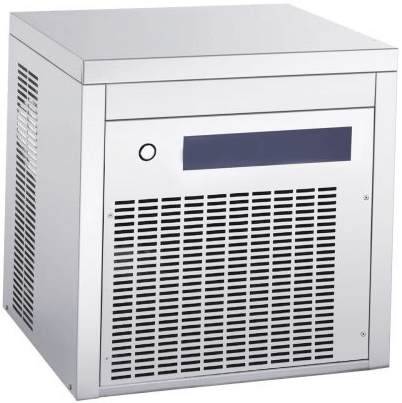

Nova Ice Machine - CP 100.60 - Full Ice Cube - 18gr

The CP 100.60 solid cube ice maker is an air-cooled, self-contained, back counter machine that is energy efficient and comprised of a full stainless steel body with foam injected polyurethane insulation to preserve ice quality. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 100 Kg of ice every 24 hours, the CP 100.60 is ideal for pubs, bars and other similar sites which require larger quantities of ice on demand. The internal ice storage bin can hold a maximum of 60 Kg of ice.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - CP 165.75 - Full Ice Cube - 18gr

The CP 165.75 solid cube ice maker is an air-cooled, self-contained, back counter machine that is energy efficient and comprised of a full stainless steel body with foam injected polyurethane insulation to preserve ice quality. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 165 Kg of ice every 24 hours, the CP 165.75 is ideal for pubs, bars and other similar sites which require larger quantities of ice on demand. The internal ice storage bin can hold a maximum of 75 Kg of ice.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - CP 300 - Full Ice Cube - 18gr

The CP 300 solid cube ice maker is an air-cooled, back stage machine that is energy efficient and comprised of a full stainless steel body with foam injected polyurethane insulation to preserve ice quality. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 300 Kg of ice every 24 hours, the CP 300 is ideal for pubs, bars and other similar sites which require larger quantities of ice. This modular ice machine will need to be paired with a separate storage bin. The benefit of having a separate storage bin instead of internal storage is that you can upgrade your storage capacity without having to get a new machine.

Find Out MoreLet's produce some ice!

How much ice do you want to produce in a 24 hour period?

Let's work out your ice consumption

To work out how much ice you want to produce, you need to make a few broad calculations based on averages. If you base your calculations on an average ice consumption of 100g (0.1Kg) per drink per customer, you can then multiply this by the amount of drinks you are serving in an hour and then multiply this by 24 to work out your consumption level. We know it seems complicated so we have created an easy to use calculator which you can launch below.

Remember, these calculations are based on averages and should be tailored to your business.

Top Tip: Give yourself breathing room when choosing your ice machine and don't go for a machine that gives you just enough ice. Ensure you have enough ice to cover your needs accounting for ice melting and customer fluctuations.

Let's produce some ice!

How much ice do you want to produce in a 24 hour period?

Thank you, nearly there

What size ice do you want?

Thank you, nearly there

What size ice do you want?

Okay, I have a couple of choices for you

What sounds best suited for you

Okay, I have a couple of choices for you

What sounds best suited for you

Okay, I have a couple of choices for you

What sounds best suited for you

Okay, I have a couple of choices for you

What sounds best suited for you

It's a match! Based on your answers I recommend:

Nova Ice Machine - CQ 150 - Dice Ice - 6gr

CQ 150 - Dice Ice cube maker is an air-cooled, back stage machine that is energy efficient and comprised of a full stainless steel body. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 140 Kg of 6g ice every 24 hours, the CQ 150 is ideal for pubs, bars and other similar sites which require larger quantities of ice. This modular ice machine will need to be paired with a separate storage bin. The benefit of having a separate storage bin instead of internal storage is that you can upgrade your storage capacity without having to get a new machine.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - CQ 250 - Dice Ice - 6gr

CQ 250 - Dice Ice cube maker is an air-cooled, back stage machine that is energy efficient and comprised of a full stainless steel body. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 240 Kg of 6g ice every 24 hours, the CQ 250 is ideal for pubs, bars and other similar sites which require larger quantities of ice. This modular ice machine will need to be paired with a separate storage bin. The benefit of having a separate storage bin instead of internal storage is that you can upgrade your storage capacity without having to get a new machine.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - CQ 150 - Dice Ice - 10gr

CQ 150 - Dice Ice cube maker is an air-cooled, back stage machine that is energy efficient and comprised of a full stainless steel body. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 140 Kg of 10g ice every 24 hours, the CQ 150 is ideal for pubs, bars and other similar sites which require larger quantities of ice. This modular ice machine will need to be paired with a separate storage bin. The benefit of having a separate storage bin instead of internal storage is that you can upgrade your storage capacity without having to get a new machine.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - CQ 250 - Dice Ice - 10gr

CQ 250 - Dice Ice cube maker is an air-cooled, back stage machine that is energy efficient and comprised of a full stainless steel body. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 240 Kg of 10g ice every 24 hours, the CQ 250 is ideal for pubs, bars and other similar sites which require larger quantities of ice. This modular ice machine will need to be paired with a separate storage bin. The benefit of having a separate storage bin instead of internal storage is that you can upgrade your storage capacity without having to get a new machine.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - CQ 320 - Dice Ice - 6gr

CQ 320 - Dice Ice cube maker is an air-cooled, back stage machine that is energy efficient and comprised of a full stainless steel body. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 300 Kg of 6g ice every 24 hours, the CQ 320 is ideal for pubs, bars and other similar sites which require larger quantities of ice. This modular ice machine will need to be paired with a separate storage bin. The benefit of having a separate storage bin instead of internal storage is that you can upgrade your storage capacity without having to get a new machine.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - CQ 450 - Dice Ice - 6gr

CQ 450 - Dice Ice cube maker is an air-cooled, back stage machine that is energy efficient and comprised of a full stainless steel body. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 450 Kg of 6g ice every 24 hours, the CQ 450 is ideal for pubs, bars and other similar sites which require larger quantities of ice. This modular ice machine will need to be paired with a separate storage bin. The benefit of having a separate storage bin instead of internal storage is that you can upgrade your storage capacity without having to get a new machine.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - CQ 320 - Dice Ice - 10gr

CQ 320 - Dice Ice cube maker is an air-cooled, back stage machine that is energy efficient and comprised of a full stainless steel body. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 300 Kg of 10g ice every 24 hours, the CQ 320 is ideal for pubs, bars and other similar sites which require larger quantities of ice. This modular ice machine will need to be paired with a separate storage bin. The benefit of having a separate storage bin instead of internal storage is that you can upgrade your storage capacity without having to get a new machine.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - CQ 450 - Dice Ice - 10gr

CQ 450 - Dice Ice cube maker is an air-cooled, back stage machine that is energy efficient and comprised of a full stainless steel body. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 450 Kg of 10g ice every 24 hours, the CQ 450 is ideal for pubs, bars and other similar sites which require larger quantities of ice. This modular ice machine will need to be paired with a separate storage bin. The benefit of having a separate storage bin instead of internal storage is that you can upgrade your storage capacity without having to get a new machine.

Find Out MoreLet's produce some ice!

How much ice do you want to produce in a 24 hour period?

Let's work out your ice consumption

To work out how much ice you want to produce, you need to make a few broad calculations based on averages. If you base your calculations on an average ice consumption of 100g (0.1Kg) per drink per customer, you can then multiply this by the amount of drinks you are serving in an hour and then multiply this by 24 to work out your consumption level. We know it seems complicated so we have created an easy to use calculator which you can launch below.

Remember, these calculations are based on averages and should be tailored to your business.

Top Tip: Give yourself breathing room when choosing your ice machine and don't go for a machine that gives you just enough ice. Ensure you have enough ice to cover your needs accounting for ice melting and customer fluctuations.

Let's produce some ice!

How much ice do you want to produce in a 24 hour period?

Okay, I have a couple of choices for you

What sounds best suited for you

Okay, I have a couple of choices for you

What sounds best suited for you

It's a match! Based on your answers I recommend:

Nova Ice Machine - CV 25.7 - Hollow Ice Cube - 17gr

The CV range of Ice Machines stands out for its modern design and compact size. This machine produces hollow bullet-shaped ice cubes perfect for the fast cooling of beverages due to their large surface area. Their hollow shape makes them easy to crush hence ideal for use in many types of cocktails. This machine uses a paddle system production method which is less susceptible to limescale build-up than other methods, increasing reliability and minimising downtime.

With its output of 25 Kg of ice every 24 hours, the CV 25.7 is ideal for pubs, bars and other similar sites which require smaller quantities of ice on demand. The internal ice storage bin can hold a maximum of 7 Kg of ice.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - CV 35.12 - Hollow Ice Cube - 17gr

The CV range of Ice Machines stands out for its modern design and compact size. This machine produces hollow bullet-shaped ice cubes perfect for the fast cooling of beverages due to their large surface area. Their hollow shape makes them easy to crush hence ideal for use in many types of cocktails. This machine uses a paddle system production method which is less susceptible to limescale build-up than other methods, increasing reliability and minimising downtime.

With its output of 35 Kg of ice every 24 hours, the CV 35.12 is ideal for pubs, bars and other similar sites which require smaller quantities of ice on demand. The internal ice storage bin can hold a maximum of 12 Kg of ice.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - CV 60.28 - Hollow Ice Cube - 17gr

The CV range of Ice Machines stands out for its modern design and compact size. This machine produces hollow bullet-shaped ice cubes perfect for the fast cooling of beverages due to their large surface area. Their hollow shape makes them easy to crush hence ideal for use in many types of cocktails. This machine uses a paddle system production method which is less susceptible to limescale build-up than other methods, increasing reliability and minimising downtime.

With its output of 60 Kg of ice every 24 hours, the CV 60.28 is ideal for pubs, bars and other similar sites which require a larger quantity of ice on demand. The internal ice storage bin can hold a maximum of 28 Kg of ice.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - CV 90.40 - Hollow Ice Cube - 17gr

The CV range of Ice Machines stands out for its modern design and compact size. This machine produces hollow bullet-shaped ice cubes perfect for the fast cooling of beverages due to their large surface area. Their hollow shape makes them easy to crush hence ideal for use in many types of cocktails. This machine uses a paddle system production method which is less susceptible to limescale build-up than other methods, increasing reliability and minimising downtime.

With its output of 90 Kg of ice every 24 hours, the CV 90.40 is ideal for pubs, bars and other similar sites which require a larger quantity of ice on demand. The internal ice storage bin can hold a maximum of 40 Kg of ice.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - CV 150.70 - Hollow Ice Cube - 17gr

The CV range of Ice Machines stands out for its modern design and compact size. This machine produces hollow bullet-shaped ice cubes perfect for the fast cooling of beverages due to their large surface area. Their hollow shape makes them easy to crush hence ideal for use in many types of cocktails. This machine uses a paddle system production method which is less susceptible to limescale build-up than other methods, increasing reliability and minimising downtime.

With its output of 140 Kg of ice every 24 hours, the CV 150.70 is ideal for pubs, bars and other similar sites which require a larger quantity of ice on demand. The internal ice storage bin can hold a maximum of 70 Kg of ice.

Find Out MoreLet's produce some ice!

How much ice do you want to produce in a 24 hour period?

Let's work out your ice consumption

To work out how much ice you want to produce, you need to make a few broad calculations based on averages. If you base your calculations on an average ice consumption of 100g (0.1Kg) per drink per customer, you can then multiply this by the amount of drinks you are serving in an hour and then multiply this by 24 to work out your consumption level. We know it seems complicated so we have created an easy to use calculator which you can launch below.

Remember, these calculations are based on averages and should be tailored to your business.

Top Tip: Give yourself breathing room when choosing your ice machine and don't go for a machine that gives you just enough ice. Ensure you have enough ice to cover your needs accounting for ice melting and customer fluctuations.

Let's produce some ice!

How much ice do you want to produce in a 24 hour period?

Okay, I have a couple of choices for you

What sounds best suited for you

Okay, I have a couple of choices for you

What sounds best suited for you

It's a match! Based on your answers I recommend:

Nova Ice Machine - SG 100.15 - Granular Ice

The SG 100.15 - Granular Ice maker is an air-cooled, self-contained, back counter machine that is energy efficient and comprised of a full stainless steel body with foam injected polyurethane insulation to preserve ice quality. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 100 Kg of granular ice every 24 hours, the SG 100.15 is ideal for pubs, cocktail bars, fast-food outlets, hotels, supermarkets and transport and packaging operations. The internal ice storage bin can hold a maximum of 15 Kg of ice.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - SG 140.25 - Granular Ice

The SG 140.25 - Granular Ice maker is an air-cooled, self-contained, back counter machine that is energy efficient and comprised of a full stainless steel body with foam injected polyurethane insulation to preserve ice quality. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 140 Kg of granular ice every 24 hours, the SG 140.25 is ideal for pubs, cocktail bars, fast-food outlets, hotels, supermarkets and transport and packaging operations. The internal ice storage bin can hold a maximum of 25 Kg of ice.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - SG 300 - Granular Ice

The SG 300 - Granular Ice maker is an air-cooled, back stage machine that is energy efficient and comprised of a full stainless steel body with foam injected polyurethane insulation to preserve ice quality. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 300 Kg of granular ice every 24 hours, the SG 300 is ideal for pubs, cocktail bars, fast-food outlets, hotels, supermarkets and transport and packaging operations. This modular ice machine will need to be paired with a separate storage bin. The benefit of having a separate storage bin instead of internal storage is that you can upgrade your storage capacity without having to get a new machine.

Find Out MoreIt's a match! Based on your answers I recommend:

Nova Ice Machine - SG 600 - Granular Ice

The SG 600 - Granular Ice maker is an air-cooled, back stage machine that is energy efficient and comprised of a full stainless steel body with foam injected polyurethane insulation to preserve ice quality. This model incorporates all the latest technology to ensure maximum efficiency and enduring performance.

With its output of 600 Kg of granular ice every 24 hours, the SG 600 is ideal for pubs, cocktail bars, fast-food outlets, hotels, supermarkets and transport and packaging operations. This modular ice machine will need to be paired with a separate storage bin. The benefit of having a separate storage bin instead of internal storage is that you can upgrade your storage capacity without having to get a new machine.

Find Out MoreLet's find the perfect dishwasher for you

What are your dishwashing requirements?

That's a lot of washing up!

It sounds like you need a specialist machine

I want to make sure you get the right advice and product recommendations, so I am going to refer you to our brainy office team. Give them a call, and they will be able to provide the best machine for you.

Get In Contact With UsIt's going to be an under-counter machine you want

What are you going to be washing?

It sounds like you need an under-counter utensil washer

I want to make sure you get the right advice and product recommendations, so I am going to refer you to our brainy office team. Give them a call, and they will be able to provide the best machine for you.

Get In Contact With UsSounds good

Do you require Thermal Disinfection?

We hope this helps your decision

What is Thermal Disinfection?

Thermal Disinfection is most effective at 82°C, which means that ALL viruses and bacteria will perish when exposed. With a large volume of crockery used in these environments every day, the risk of contamination is high. By using a dishwashing machine with a Thermal Disinfection cycle, you can be sure that all bacteria will be eliminated.

So, do you require thermal disinfection

It's a match! Based on your answers I recommend:

TD50 Thermal Dishwasher - 30 Amp

The TD50 has been designed and built for the Healthcare sector. The TD50 is a Thermal Disinfection machine that provides the most hygienic wash to all crockery and utensils. Thermal Disinfection is most effective at 82°C, which means that ALL viruses and bacteria will perish when exposed.

The TD50 Thermal Disinfection cycle is set for a 2-minute rinse at 82°C, followed by a cooling rinse to ensure the crockery and tableware is safe to handle when removing it from the dishwasher. The thermal rinse cycle activates a special door lock for the duration of the rinse so that the door cannot be opened while the machine is performing a cycle, thus resulting in no risk of re-introducing bacteria.

Find Out MoreIt's a match! Based on your answers I recommend:

Jubilee 50 Dishwasher - 30 Amp

The Jubilee 50 Dishwasher offers three wash cycles for the best washing results. A Light, Medium and Heavy Soiled Cycle can be chosen to ensure that the right wash is used each time.

A Light Soil Cycle provides a 2-minute wash cycle for lightly soiled items. A Normal Soil Cycle provides a 3-minute wash cycle for light/heavy soiled items – this is the default cycle type when the machine is switched on. A Heavy Soil Cycle provides a 4-minute wash cycle for all items that are heavily soiled and take a little longer to get the best cleaning results.

No matter which cycle is selected, every cycle uses fresh water for its wash; this means the same consistent cleaning results are delivered every time.

Find Out MoreIt's going to be a hood machine you want

What are you going to be washing?

It sounds like you need a dedicated utensil washer

I want to make sure you get the right advice and product recommendations, so I am going to refer you to our brainy office team. Give them a call, and they will be able to provide the best machine for you.

Get In Contact With UsSounds good

Which type of machine do you want?

We hope this helps your decision

Difference in skin types

Single skin machines tend to be cheaper but less energy efficient as heat escapes through the single skin exterior. A double skin hood dishwasher, on the other hand, can be more expensive but far more energy-efficient due to the fact there is an air gap between the two layers. This double skin acts as an insulator and keeps heat in, and avoids it escaping, which heats its surroundings and makes for an uncomfortable environment. Another advantage of the double skin variations is with noise insulation; double skin machines tend to be a lot quieter thanks to its dual exterior.

So, what type of machine do you want?

Nearly there!

What kind of washing power do you need?

It's a match! Based on your answers I recommend:

Regent Hood Dishwasher SS - EH 850E PRS

Purchasing a commercial dishwasher is an investment to your kitchen, so it's essential to choose a premium product that keeps up with your busy kitchen and meets stringent quality checks. Any appliance in the UK that when installed will carry or receive water from the public mains water supply cannot cause waste, undue consumption or contamination of the water supply and must be 'of an appropriate quality and standard' this is where WRAS approval comes in. The Regent Hood Dishwasher is WRAS approved with a 'Type A' air gap which completely prevents any dirty water from going back into the mains water supply. Being WRAS approved means this dishwasher has been tested under pressure and has passed all checks and is in full compliance with regulations.

This hood dishwasher also utilises the PRS (Premium Rinse System). The PRS oversees every detail of the rinse cycle given the combination of the break tank, the atmospheric boiler and the rinse pump. By using PRS, the dishwasher doesn't need to rely on the network's water pressure; it can function perfectly well with just 1 bar! With the PRS you can guarantee a constant temperature and output pressure, with optimum water and chemical consumption, you can ensure high levels of hygiene and overall sanitation.

Find Out MoreIt's a match! Based on your answers I recommend:

Regent Hood Dishwasher SS - EH 1200E PRS

Purchasing a commercial dishwasher is an investment to your kitchen, so it's essential to choose a premium product that keeps up with your busy kitchen and meets stringent quality checks. Any appliance in the UK that when installed will carry or receive water from the public mains water supply cannot cause waste, undue consumption or contamination of the water supply and must be 'of an appropriate quality and standard' this is where WRAS approval comes in. The Regent Hood Dishwasher is WRAS approved with a 'Type A' air gap which completely prevents any dirty water from going back into the mains water supply. Being WRAS approved means this dishwasher has been tested under pressure and has passed all checks and is in full compliance with regulations.

This hood dishwasher also utilises the PRS (Premium Rinse System). The PRS oversees every detail of the rinse cycle given the combination of the break tank, the atmospheric boiler and the rinse pump. By using PRS, the dishwasher doesn't need to rely on the network's water pressure; it can function perfectly well with just 1 bar! With the PRS you can guarantee a constant temperature and output pressure, with optimum water and chemical consumption, you can ensure high levels of hygiene and overall sanitation.

Find Out MoreIt's a match! Based on your answers I recommend:

Regent Hood Dishwasher SS - EH 1500E PRS

Purchasing a commercial dishwasher is an investment to your kitchen, so it's essential to choose a premium product that keeps up with your busy kitchen and meets stringent quality checks. Any appliance in the UK that when installed will carry or receive water from the public mains water supply cannot cause waste, undue consumption or contamination of the water supply and must be 'of an appropriate quality and standard' this is where WRAS approval comes in. The Regent Hood Dishwasher is WRAS approved with a 'Type A' air gap which completely prevents any dirty water from going back into the mains water supply. Being WRAS approved means this dishwasher has been tested under pressure and has passed all checks and is in full compliance with regulations.

This hood dishwasher also utilises the PRS (Premium Rinse System). The PRS oversees every detail of the rinse cycle given the combination of the break tank, the atmospheric boiler and the rinse pump. By using PRS, the dishwasher doesn't need to rely on the network's water pressure; it can function perfectly well with just 1 bar! With the PRS you can guarantee a constant temperature and output pressure, with optimum water and chemical consumption, you can ensure high levels of hygiene and overall sanitation.

Find Out MoreNearly there!

What kind of washing power do you need?

Final question, I promise!

Do you require the Energy Recovery System

We hope this helps your decision

The Energy Recovery System

Our rage of hood dishwashers have been engineered with a ERS (Energy Recovery System) which uses the power of steam to reduce your energy expenditure saving you money! The ERS takes the steam from your dishwasher and uses it to pre-heat the cold water that is entering the dishwasher at no extra cost. By utilising the steam created by the dishwasher, you are able to save up to 50% of your energy usage during the step of heating water.

So, do you want the Energy Recovery System?

It's a match! Based on your answers I recommend:

Regent Hood Energy Recovery Dishwasher - EH 850E ES

The carefully engineered ERS (Energy Recovery System) uses the power of steam to reduce your energy expenditure saving you money! Reducing your energy use is crucial in protecting the environment and minimising your running costs which is where the ERS comes in, benefiting you and the environment.

As your machine is running and heating up water, it produces steam which can fill your kitchen, making it hotter. The ERS takes this steam byproduct and uses it to pre-heat the cold water that is entering the dishwasher at no extra cost. By utilising the steam created by the dishwasher, you are able to save up to 50% of your energy usage during the step of heating water. With the removal of steam, you will not need to further invest in an extractor hood which itself is costly in operation and purchase.

Find Out MoreIt's a match! Based on your answers I recommend:

Regent Hood Dishwasher DS - EH 850E PRS

Purchasing a commercial dishwasher is an investment to your kitchen, so it's essential to choose a premium product that keeps up with your busy kitchen and meets stringent quality checks. Any appliance in the UK that when installed will carry or receive water from the public mains water supply cannot cause waste, undue consumption or contamination of the water supply and must be 'of an appropriate quality and standard' this is where WRAS approval comes in. The Regent Hood Dishwasher is WRAS approved with a 'Type A' air gap which completely prevents any dirty water from going back into the mains water supply. Being WRAS approved means this dishwasher has been tested under pressure and has passed all checks and is in full compliance with regulations.

This hood dishwasher also utilises the PRS (Premium Rinse System). The PRS oversees every detail of the rinse cycle given the combination of the break tank, the atmospheric boiler and the rinse pump. By using PRS, the dishwasher doesn't need to rely on the network's water pressure; it can function perfectly well with just 1 bar! With the PRS you can guarantee a constant temperature and output pressure, with optimum water and chemical consumption, you can ensure high levels of hygiene and overall sanitation.

Find Out MoreFinal question, I promise!

Do you require the Energy Recovery System

We hope this helps your decision

The Energy Recovery System

The carefully engineered ERS (Energy Recovery System) uses the power of steam to reduce your energy expenditure saving you money! The ERS takes the steam from your dishwasher and uses it to pre-heat the cold water that is entering the dishwasher at no extra cost. By utilising the steam created by the dishwasher, you are able to save up to 50% of your energy usage during the step of heating water.

So, do you want the Energy Recovery System?

It's a match! Based on your answers I recommend:

Regent Hood Energy Recovery Dishwasher - EH 1200E ES

The carefully engineered ERS (Energy Recovery System) uses the power of steam to reduce your energy expenditure saving you money! Reducing your energy use is crucial in protecting the environment and minimising your running costs which is where the ERS comes in, benefiting you and the environment.

As your machine is running and heating up water, it produces steam which can fill your kitchen, making it hotter. The ERS takes this steam byproduct and uses it to pre-heat the cold water that is entering the dishwasher at no extra cost. By utilising the steam created by the dishwasher, you are able to save up to 50% of your energy usage during the step of heating water. With the removal of steam, you will not need to further invest in an extractor hood which itself is costly in operation and purchase.

Find Out MoreIt's a match! Based on your answers I recommend:

Regent Hood Dishwasher DS - EH 1200E PRS

Purchasing a commercial dishwasher is an investment to your kitchen, so it's essential to choose a premium product that keeps up with your busy kitchen and meets stringent quality checks. Any appliance in the UK that when installed will carry or receive water from the public mains water supply cannot cause waste, undue consumption or contamination of the water supply and must be 'of an appropriate quality and standard' this is where WRAS approval comes in. The Regent Hood Dishwasher is WRAS approved with a 'Type A' air gap which completely prevents any dirty water from going back into the mains water supply. Being WRAS approved means this dishwasher has been tested under pressure and has passed all checks and is in full compliance with regulations.

This hood dishwasher also utilises the PRS (Premium Rinse System). The PRS oversees every detail of the rinse cycle given the combination of the break tank, the atmospheric boiler and the rinse pump. By using PRS, the dishwasher doesn't need to rely on the network's water pressure; it can function perfectly well with just 1 bar! With the PRS you can guarantee a constant temperature and output pressure, with optimum water and chemical consumption, you can ensure high levels of hygiene and overall sanitation.

Find Out MoreFinal question, I promise!

Do you require the Energy Recovery System

We hope this helps your decision

The Energy Recovery System

The carefully engineered ERS (Energy Recovery System) uses the power of steam to reduce your energy expenditure saving you money! The ERS takes the steam from your dishwasher and uses it to pre-heat the cold water that is entering the dishwasher at no extra cost. By utilising the steam created by the dishwasher, you are able to save up to 50% of your energy usage during the step of heating water.

So, do you want the Energy Recovery System?

It's a match! Based on your answers I recommend:

Regent Hood Energy Recovery Dishwasher - EH 1500E ES

The carefully engineered ERS (Energy Recovery System) uses the power of steam to reduce your energy expenditure saving you money! Reducing your energy use is crucial in protecting the environment and minimising your running costs which is where the ERS comes in, benefiting you and the environment.

As your machine is running and heating up water, it produces steam which can fill your kitchen, making it hotter. The ERS takes this steam byproduct and uses it to pre-heat the cold water that is entering the dishwasher at no extra cost. By utilising the steam created by the dishwasher, you are able to save up to 50% of your energy usage during the step of heating water. With the removal of steam, you will not need to further invest in an extractor hood which itself is costly in operation and purchase.

Find Out MoreIt's a match! Based on your answers I recommend:

Regent Hood Dishwasher DS - EH 1500E PRS

Purchasing a commercial dishwasher is an investment to your kitchen, so it's essential to choose a premium product that keeps up with your busy kitchen and meets stringent quality checks. Any appliance in the UK that when installed will carry or receive water from the public mains water supply cannot cause waste, undue consumption or contamination of the water supply and must be 'of an appropriate quality and standard' this is where WRAS approval comes in. The Regent Hood Dishwasher is WRAS approved with a 'Type A' air gap which completely prevents any dirty water from going back into the mains water supply. Being WRAS approved means this dishwasher has been tested under pressure and has passed all checks and is in full compliance with regulations.

This hood dishwasher also utilises the PRS (Premium Rinse System). The PRS oversees every detail of the rinse cycle given the combination of the break tank, the atmospheric boiler and the rinse pump. By using PRS, the dishwasher doesn't need to rely on the network's water pressure; it can function perfectly well with just 1 bar! With the PRS you can guarantee a constant temperature and output pressure, with optimum water and chemical consumption, you can ensure high levels of hygiene and overall sanitation.

Find Out MoreTotal Cost Amount: £500.00

Initial Payment Percentage: 10%

Number Of Repayments: 3

Interest: 0.00%

Fees: £0.00

Initial Payment: £50.00

Monthly Repayment: £150.00

11 x Payments: £150.00

Final Payment: £150.00

12 x Payments: £150.00

This price excludes optional monthly payments

Please Note: By continuing and placing this order it is not a guarantee that your order will be accepted. Every spread payment order is reviewed, and we reserve the right to cancel the order if it does not meet our guidelines. If for any reason your order does not meet our guidelines and is rejected, the order and the direct debit will be cancelled and any money received will be refunded.

Payments: The direct debit and payments are processed through GoCardless. The initial payment amount will be taken 7 days from the order date. The first monthly payment will be taken one month after the initial payment and monthly after that. GoCardless will send a full schedule of payments.

Total Cost Amount: £500.00

Initial Payment Percentage: 10%

Number Of Repayments: 3

Interest: 0.00%

Fees: £0.00

Initial Payment: £50.00

Monthly Repayment: £150.00

11 x Payments: £150.00

Final Payment: £150.00

12 x Payments: £150.00

Please Note: By continuing and placing this order it is not a guarantee that your order will be accepted. Every spread payment order is reviewed, and we reserve the right to cancel the order if it does not meet our guidelines. If for any reason your order does not meet our guidelines and is rejected, the order and the direct debit will be cancelled and any money received will be refunded.

Payments: The direct debit and payments are processed through GoCardless. The initial payment amount will be taken 7 days from the order date. The first monthly payment will be taken one month after the initial payment and monthly after that. GoCardless will send a full schedule of payments.

On average, 100g of ice is served with each drink.

Roughly how many drinks do you serve in your busiest hour that require ice? drinks.

Thats 0g of ice every hour. In a six hour working session you output requirements would be around 0Kg.

When selecting your ice machine you would want a machine capable of 0Kg per 24 hours.

Roughly how many covers would you do in a typical day?

Thats around 0 racks per day.

(On average, four covers fills one rack.)

When selecting your Dishwasher you would want a machine capable of 0 racks per day.

We class this as lowmediumhigh volume.

All of our hood machines have the same cycle times regardless of power. So a more powerful machine will not increase cycle speed. When we discuss power, we relate this to the wash pump; the more powerful the machine (High Power), the more powerful the wash pump, which can give a superior wash result as the water being sprayed through the wash arms has more force.

Depending on your current set up and what you plan to wash will determine which kind of washing power you need. For example, if you can perform a good pre-rinse before putting crockery into the dishwasher, getting rid of or loosening most of the waste, then a low powered machine may suffice. Whereas if you have heavily soiled items that you are washing, you may need a high power machine.

Airack Glass Dryer - Standard - 40 Size

CS-A0051

£499.00*

This Ice Machine requires a compatible Ice Bin. Choose from the below or view the range here

Machine Installation - 1 Man

£288.00 inc. VAT

Machine Installation - 2 Man

£480.00 inc. VAT

Machine Maintenance Service - Monthly Plan

£30.00 /pm inc. VAT

Chemical Package - Monthly Plan

£19.20 /pm inc. VAT

Airack Extended Warranty - 1 Year

£60.00 inc. VAT

Airack Extended Warranty - 2 Year

£120.00 inc. VAT

Nova Ice Bin - ST S 150

£2754.00 inc. VAT

Nova Ice Bin - ST S 200

£2,874.00 inc. VAT

Nova Ice Bin - ST S 250

£3,714.00 inc. VAT

Nova Ice Bin - ST S 400

£4,314.00 inc. VAT

Nova Ice Bin - ST SD 600

£8,154.00 inc. VAT

Nova Ice Bin - ST C 50

£7,194.00 inc. VAT

Nova Ice Bin - ST C 300

£12,354.00 inc. VAT

Nova Ice Bin - ST C 600

£20,754.00 inc. VAT

Nova Ice Bin - ST C 1000

£31,674.00 inc. VAT

You can only add the Chemical Package - Monthly Plan when you have opted into the Machine Maintenance Service - Monthly Plan

Would you like to opt into the Monthly Service Plan?