About Clenaware Systems

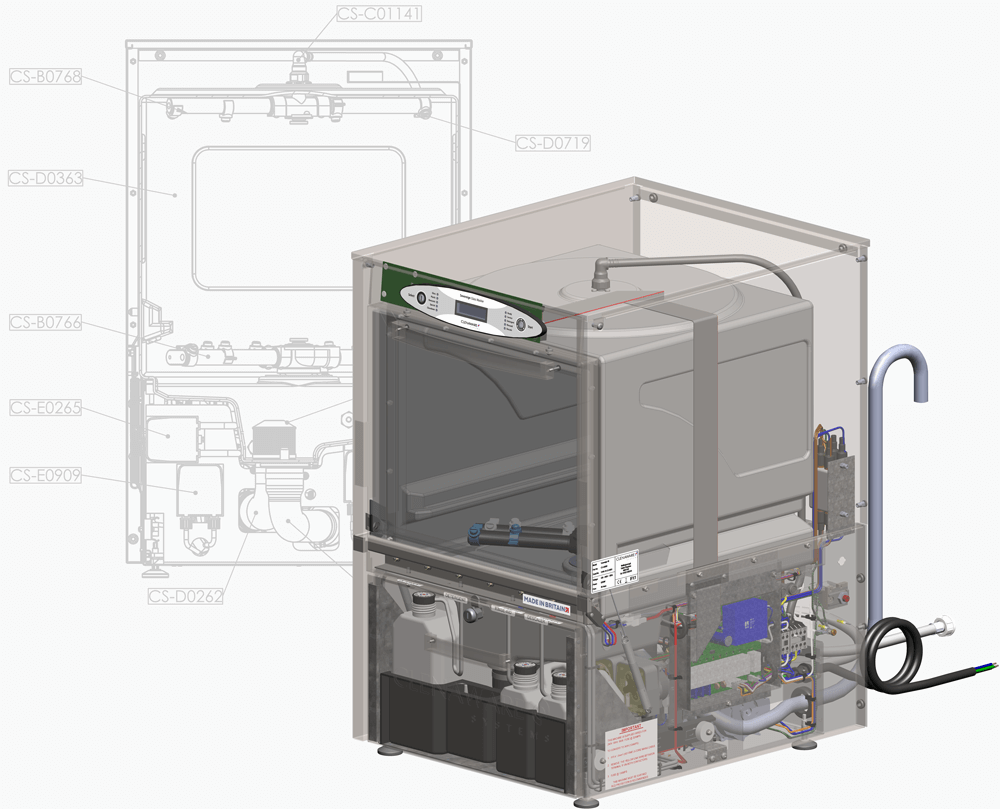

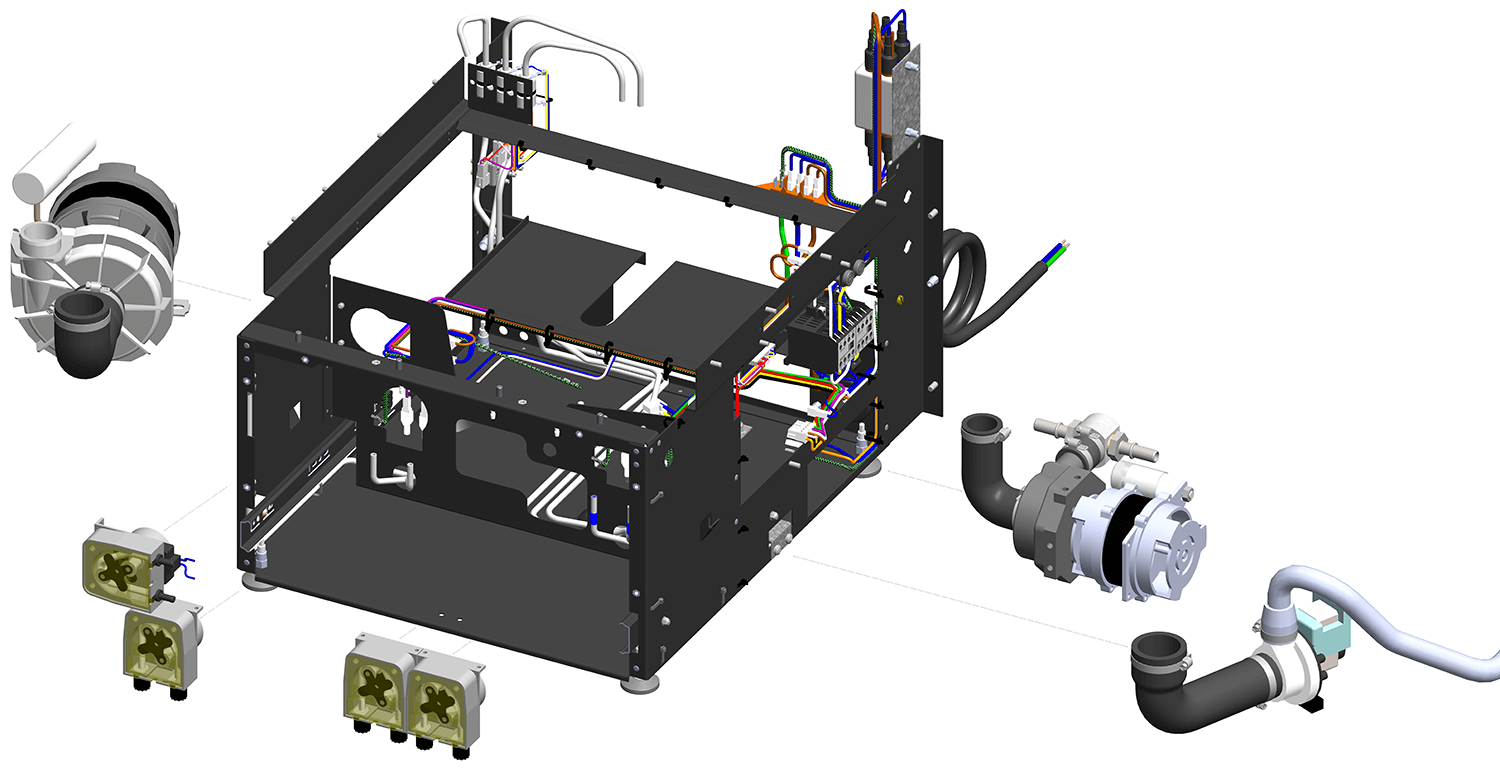

Clenaware Systems have been designing and manufacturing ware washing equipment for over 50 years. The business relocated from its roots in Farnham to Wellingborough, Northamptonshire where the Clenaware products are still designed and manufactured to the same high quality that customers have come to know.

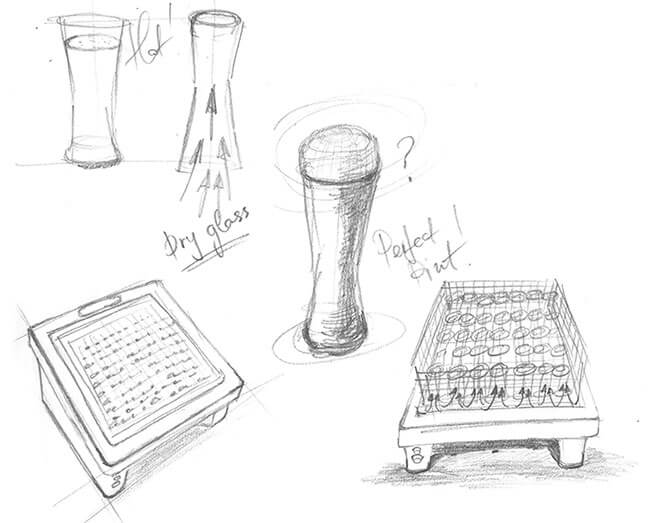

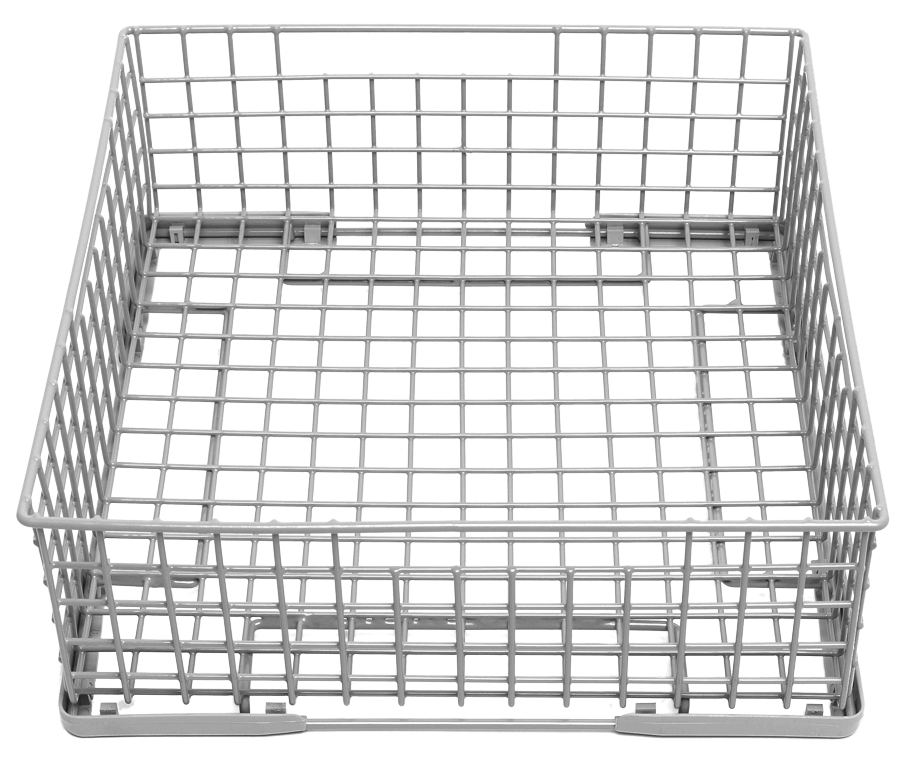

Since it started in the 1950s Clenaware Systems has moved from the very first brush glass cleaning machine to the latest front-loading Glass Washer and Dishwasher. We are proud that our Glass Washers, Dishwashers and accessories are designed and hand-built in our UK based factory.

At Clenaware we are passionate about our brand and our products. We believe everything we do, from design and manufacturing, through to the after sales and service we provide, should achieve that goal of ‘Delivering Perfect Results’ every time. At Clenaware ‘Excellence comes as standard’.